When selecting an API pump for a specific application, it’s crucial to consider the unique requirements of your system. This involves analyzing various factors that can significantly impact the pump’s performance and suitability.

Understanding the Fluid Characteristics

The type of fluid you need to transport plays a vital role in choosing the right API pump. Assessing fluid characteristics such as viscosity, temperature, and corrosiveness will help determine the appropriate pump materials and design. For example, handling highly viscous or abrasive fluids may require specialized materials or coatings to ensure longevity and efficiency.

Determining Flow Rate and Pressure Needs

Accurate assessment of flow rate and pressure requirements is essential for optimal pump selection. Calculating these parameters helps in choosing a pump that can handle the demands of your application without overloading or underperforming. It’s important to select a pump that meets both current and future needs, allowing for operational flexibility.

Evaluating Environmental Conditions

Environmental conditions such as ambient temperature, humidity, and potential exposure to hazardous substances should be considered when selecting an API pump. These factors can affect the pump’s operation and lifespan. Selecting a pump with appropriate seals and enclosures will help mitigate environmental impacts.

How Do API Standards Influence Pump Selection?

API standards are critical in guiding the selection process for pumps used in industrial applications. These standards ensure reliability, safety, and efficiency across various industries.

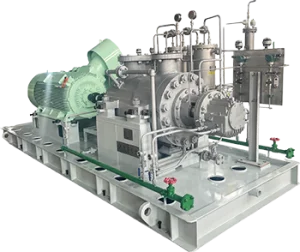

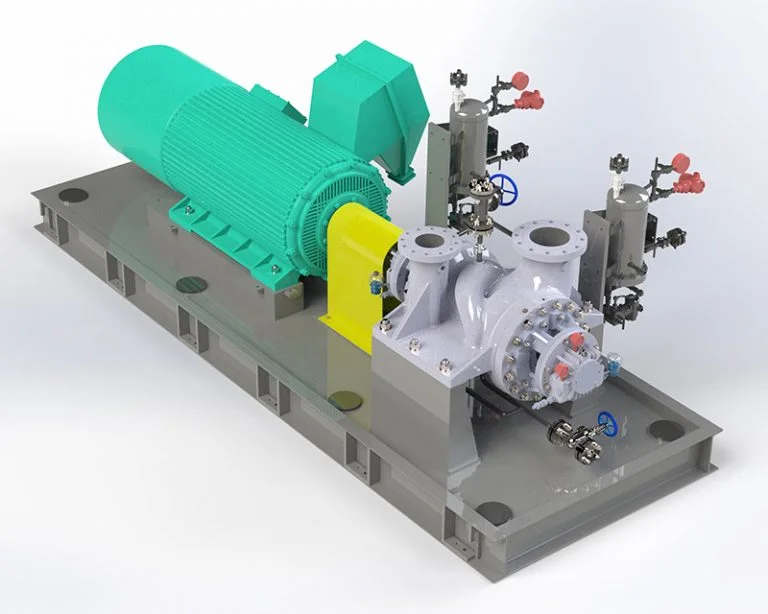

Exploring API Pump Types and Classifications

API pumps come in different types and classifications tailored for specific applications. Understanding these classifications helps you choose a pump that aligns with your operational needs while adhering to industry standards. Each type offers unique features suited for different applications, whether it’s handling crude oil or chemical processing.

Compliance with Industry Standards

Compliance with API standards is non-negotiable for ensuring safety and operational efficiency. These standards dictate design specifications, testing protocols, and performance criteria that pumps must meet. By adhering to these guidelines, you ensure that your chosen API pump will perform reliably under specified conditions.

For more detailed guidance on selecting the right API pumps, consider consulting with experts like Yantai Longgang Pump Industry, who offer comprehensive Services including technical advisory services tailored to your specific needs. Additionally, explore their range of API pumps designed to meet high industry standards.

Why Is Material Selection Crucial for API Pumps?

Material selection is a fundamental aspect when choosing API pumps, as it directly impacts the pump’s durability, efficiency, and compatibility with the fluid being handled. Different materials offer varying levels of resistance to corrosion, wear, and chemical reactions, making it essential to select the right one for your application.

Assessing Material Compatibility

When evaluating material compatibility, consider the chemical properties of the fluid being pumped. Corrosive fluids require materials that can withstand chemical attacks without degrading. For instance, stainless steel or high-nickel alloys might be necessary for handling aggressive chemicals. Additionally, consider the temperature and pressure conditions under which the pump will operate, as these factors can influence material performance.

Selecting Appropriate Sealing Solutions

Sealing solutions are critical in preventing leaks and maintaining system integrity. The choice of seals depends on the fluid type and operating conditions. Mechanical seals are commonly used in API pumps due to their reliability in high-pressure environments. Ensure that the selected seal materials are compatible with both the pump materials and the fluid to avoid premature failure.

How Does Maintenance Impact Your Choice of API Pumps?

Maintenance considerations play a significant role in selecting an API pump. A well-maintained pump ensures long-term operational efficiency and reduces downtime, which is crucial for industrial applications.

Planning for Routine Maintenance

Routine maintenance involves regular inspection and servicing of pumps to identify potential issues before they lead to failures. When choosing an API pump, consider its ease of maintenance. Pumps with modular designs or those that allow easy access to components can significantly reduce maintenance time and costs.

Considering Long-Term Operational Costs

Long-term operational costs include not just maintenance expenses but also energy consumption and potential downtime costs. Opt for pumps that offer energy-efficient operation to minimize electricity usage over time. Additionally, selecting a pump with readily available spare parts can reduce downtime during repairs or maintenance activities.

For expert guidance on selecting API pumps tailored to your needs, consider consulting Yantai Longgang Pump Industry, renowned for their extensive range of API pumps designed to meet stringent industry standards. Their comprehensive Services include technical advisory services that ensure you make informed decisions based on your specific application requirements.

What Role Does Customization Play in Selecting API Pumps?

Customization is a vital factor when selecting API pumps, as it allows you to tailor the pump to meet the specific needs of your application. This flexibility ensures that the pump performs optimally under your unique operational conditions.

Tailoring Pumps to Meet Unique Application Needs

Customizing an API pump involves adjusting its design and materials to suit the particular demands of your application. This might include modifying the pump’s size, capacity, or material composition to handle specific fluid characteristics or environmental conditions. By working closely with manufacturers like Yantai Longgang Pump Industry, you can ensure that your pump is perfectly suited to your operational requirements.

Leveraging Technical Advisory Services

Technical advisory services are invaluable when customizing API pumps. These services provide expert guidance on selecting the right pump specifications and configurations for your application. By consulting with professionals, you can address technical challenges and optimize pump performance. Companies offering comprehensive Services can help you navigate these decisions, ensuring that you select a pump that meets both current and future operational needs.

Where Can You Source Reliable API Pumps?

Finding a reliable source for API pumps is crucial for ensuring quality and performance in industrial applications. It involves identifying reputable manufacturers who offer robust support and service offerings.

Identifying Reputable Manufacturers

When sourcing API pumps, it’s important to choose manufacturers with a proven track record of quality and reliability. Look for companies with extensive experience in the industry and a commitment to adhering to stringent standards. Yantai Longgang Pump Industry is one such manufacturer, known for supplying high-quality pumps to major petrochemical companies.

Evaluating Supplier Support and Service Offerings

The level of support and services offered by suppliers can significantly impact your experience with API pumps. Consider manufacturers who provide comprehensive after-sales services, including technical advisory support, maintenance assistance, and readily available spare parts. This ensures that any issues are promptly addressed, minimizing downtime and maintaining operational efficiency.

For more information on sourcing reliable API pumps, explore the range of products offered by Yantai Longgang Pump Industry. Their expertise in providing tailored solutions ensures that you receive pumps designed to meet high industry standards while benefiting from exceptional service support.