Multistage pumps are designed to generate high pressure and facilitate the transportation of various fluids in numerous industrial applications. These pumps operate using multiple impellers or stages, which effectively raises the fluid’s pressure and moves it through a piping system. Multistage pumps are particularly advantageous when dealing with applications that require significant elevation change or high pressure. They are commonly used in water treatment, irrigation, and chemical processing, among other industries.

Types of Multistage Pumps

There are mainly two kinds of multistage pumps. The horizontal type is designed with the motor. Pump casing aligned in a manner and is best suited for applications that need high flow rates and moderate pressure levels.On the contrary the vertical multistage pumps have a layout which’s beneficial for installations where space is limited as they take up less floor space.These pumps can be tailored to meet needs. Knowing the distinctions between them aids in choosing the right pump for a given application.

How Do Horizontal Multistage Pumps Operate?

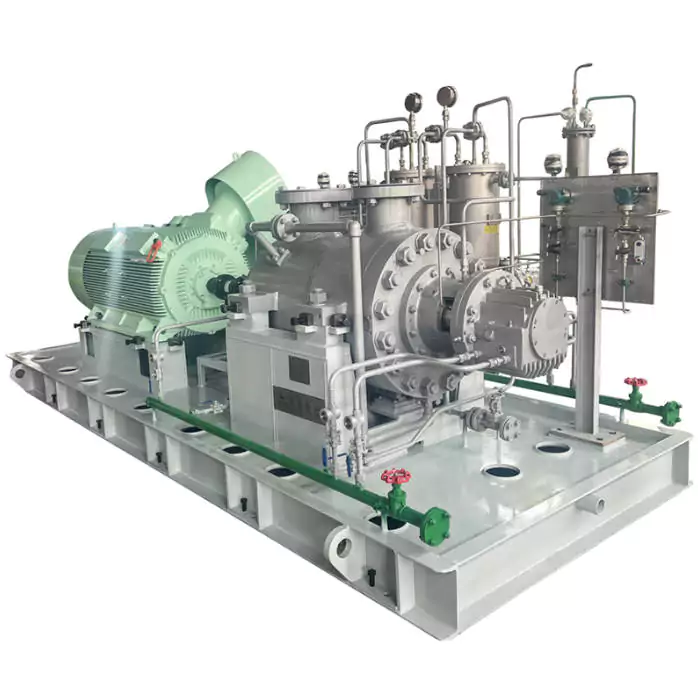

Horizontal multistage pumps consist of multiple impellers mounted on a single shaft within a horizontal casing. The design includes a series of stages, with each stage consisting of an impeller and a diffuser that helps to convert the kinetic energy from the impeller into pressure. This configuration allows the pump to achieve higher pressures than single-stage pumps. The construction typically emphasizes robust materials to withstand demanding conditions and ensure longevity.

Operational Efficiency and Performance

Horizontal multistage pumps are known for their efficiency, in handling flow rates and pressures due to their design structure with multiple stages involved in the process of energy utilization optimization to mitigate the risk of cavitation that can harm pump performance and durability significantly. These pumps are versatile as they can be tailored for uses by incorporating impeller designs and motor choices according to the requirements of the application they are intended for. The superior efficiency of these pumps makes them a popular option, for applications that involve transferring volumes of liquid while ensuring energy consumption.

Applications of Horizontal Multistage Pumps

Horizontal multistage pumps are highly versatile. They can be used in a range of applications such, as water supply systems and irrigation well as for boiler feedwater and industrial processes.They are commonly utilized in water systems to aid in the distribution of water throughout networks.They also play a role in fire protection systems by providing the required pressure to effectively fight fires. Due to their adaptability and efficiency horizontal multistage pumps have become indispensable in commercial settings.

How Do Vertical Multistage Pumps Operate?

Vertical multistage pumps are crafted to be used in situations where space is restricted by adopting a layout that takes up space compared to horizontal models. In addition, to having several impellers mounted on a shaft like their counterparts in the design category,these pumps are built with a vertical casing that provides stability for both the motor and pump components. The fluid entering from the top is guided downwards through impeller stages before being released at the lower end.

Operational Efficiency and Performance

Vertical multistage pumps excel in performance when dealing with pressures and lower flow rates in applications.Their design enables them to effectively manage head conditions while maintaining a performance curve. Additionally due to their setup such pumps can minimize the required installation and maintenance area resulting in cost savings.The flexibility to adjust impeller sizes and stage counts makes these pumps adaptable to address dynamics requirements, in different sectors.

Applications of Vertical Multistage Pumps

Vertical multistage pumps find a range of uses, in scenarios where space constraints are a concern.They are frequently employed in HVAC systems to facilitate the movement of water for heating and cooling purposes.Additionally you can see them being essential in tasks likefood processing operations.Their ability to handle high pressure environments efficiently makes them vital components across fields catering specifically to the unique requirements of diverse fluid management processes.

Benefits of Using Horizontal vs. Vertical Multistage Pumps

When comparing the benefits of using horizontal vs. vertical multistage pumps, it is important to consider their suitability for different environments and compare their energy efficiency.

Suitability for Different Environments

When deciding between vertical multistage pumps the environments suitability is a factor to consider. Horizontal multistage pumps are best for settings with installation space as they necessitate alignment,suitable for open spaces or expansive establishments that can accommodate their width.On the hand in spaces the compact design of vertical multistage pumps stands out,vertical pumps can easily fit into cramped spaces, like basements or equipment rooms due to their versatility.they are commonly chosen for use in skyscrapers and populated industrial areas.

Comparative Energy Efficiency

Considering energy efficiency is crucial when choosing pumps for applications that involve long term expenses. Horizontal multistage pumps are known for their energy efficiency at increased flow rates. They are commonly utilized in settings such as municipal water supply and large scale industrial operations. Their construction is designed to minimize energy wastage during use leading to reduced expenses in the term. On the hand vertical multistage pumps perform better under high pressure scenarios. They are perfect for tasks that require boosting pressure and saving energy to manage costs effectively. Knowing these efficiency details can guide us in making choices tailored to our operational requirements.

Challenges and Limitations of Each Type

It’s important to grasp the difficulties and restrictions associated with pump types. Being mindful of the problems that may occur with horizontal multistage pumps in addition, to the issues faced by Vertical Multistage Pumps.

Common Issues with Horizontal Multistage Pumps

While horizontal multistage pumps offer benefits they do come with their share of challenges as well. One common issue they face is cavitation susceptibility, especially when used beyond their operating conditions. Cavitation arises when the fluid pressure locally drops below its vapor pressure potentially causing damageto the pump. Regular upkeep and monitoring are essential to prevent issues as repairs can be quite pricey and time consuming. Moreover horizontal pumps may encounter alignment difficulties, necessitating installation and periodic adjustments to maintain efficiency and integrity.

Common Issues with Vertical Multistage Pumps

Vertical multi stage pumps offer advantages. Also come with certain drawbacks that can affect their performance negatively in some situations. One common issue is the accumulation of sediment at the pumps base which can impede its operation and decrease efficiency. Problematic when dealing with applications that involve high solid concentrations or abrasive liquids. Moreover, due to their design,these pumps need alignment during setup to function properly Incorrect installation may result in vibration and erosion issues, leading to additional maintenance requirements. By grasping these concerns we can take steps to reduce risks and guarantee sustained achievements in the long run.

Yantai Longgang Pump Industry: Your Trusted Partner in Pump Solutions

For those in the field looking for pump solutions to meet our business needs reliably and efficiently Yantai Longgang Pump Industry emerges as a trusted and esteemed partner of choice.We specialize in offering an array of vertical multistage pumps designed meticulously to cater to a variety of operational demands.Our strong emphasis on quality and innovation ensures that each pump is crafted from materials ideal, for high pressure usage.Moreover Yantai Longgang Pump Industry provides expert advice to assist you in making decisions regarding pump selection and system design tailored to your specific needs.

Yantai Longgang not only provides top notch products but also puts a strong emphasis on customer support and training to assist clients in maximizing pump performance and reducing operational challenges. Recognizing the role multistage pumps play across industries we offer extended warranties and maintenance services to ensure long term operations. When businesses opt for Yantai Longgang Pump Industry we can count on having a partner to tackle our requirements and obstacles supporting fluid handling and improved efficiency.