In the area of pumping systems, the BB2 and BB1 pumps have raised efficiency and performance levels in several industrial applications. These two types of pumps play an important role in different applications but are both designed from important and relevant specifications that work best when tackling different operational needs. By grasping these differences you will be able to choose the right pump for your application for maximum performance and reliability.

Overview of BB2 and BB1 Pumps

Introduction to BB1 Pump

For decades the BB1 pump has been a shelter standard for efficacy, dependability, and broad fluid transport applications. The same thing construction has allowed for this pump’s use in many industries including chemical and oil. While the BB1 pump is aimed at medium-duty service, its commendable flow rates and fair handling of different fluid types ensure that it is in regular short-list decisions for a wide range of applications. It’s still a reliable selection for lots of use instances, however there are higher solutions to be had.

Introduction to BB2 Pump

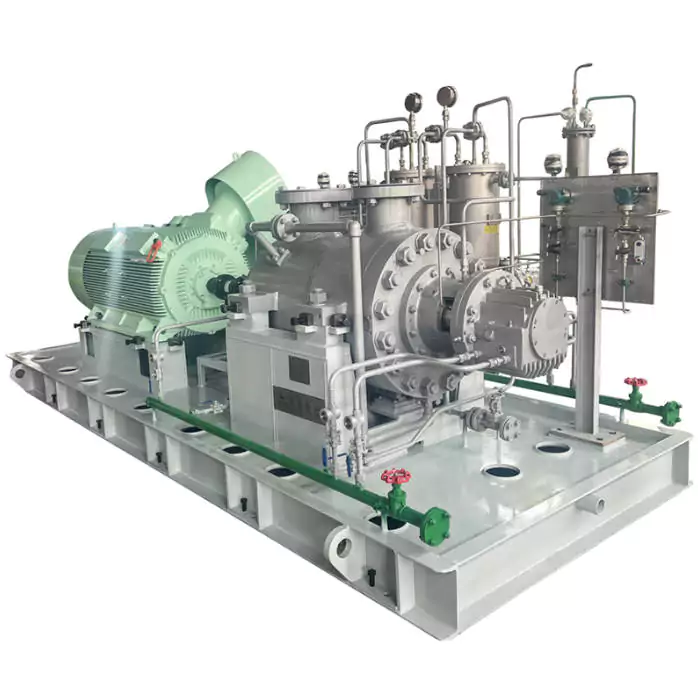

Enter the BB2 pump, an upgraded version designed for high-demand applications. The BB2 is an operational efficiency upgrade for different applications like crude oil transportation and natural gas processing. By employing state-of-the-art technology and the latest design innovations, this pump delivers a hydraulic optimum efficiency point that exceeds other model units. The capability to manage larger flow rates and offer higher resistance to corrosive chemicals distinguishes it as an option that draws the attention of professionals.

Design Specifications

Design specifications enable deeper insights into pump functionality and life when selecting a pump. There are structural and material differences between BB2 and BB1 pumps. The difference between the BB2 and BB1 pumps is mainly in their general structural designs and material composition.

Structural Differences

Instead, the structural design of the BB2 pump is considerably different from its predecessor BB1 because utilizes optimized geometries for better hydraulic performance. The BB2 incorporates a more aerodynamic internal design that promotes a laminar rather than turbulent flow of fluids. Conversely, the BB1 pump employs a more traditional configuration and will likely not maximize energy efficiency to the same extent. BB2’s so-called ‘advanced structure’ isn’t just a step up, it’s an entire architecture designed to handle industrial-level requirements.

Material Composition

In a pump application, especially ones that have to worry about corrosive fluids, Material selection becomes very important. The BB1 pump is usually constructed from common anti-corrosive materials only, which means that it has limited applicability. On the other hand, there’s no limiting factor in such a way for the BB2 pump. The company also introduced pumps made from super-low carbon duplex stainless steel, the basis of the high-performance Longbrook pump for corrosive fluids. These will resist workhorse chemicals like sulfuric and hydrochloric acid; perfect for tougher applications.

Performance Capabilities

Truth: The performance capability of these pumps is visible in the assessment. This is where the differences become clearer, as the design of the BB2 pump offers more efficient fluid handling and lower energy consumption. With the BB2 pump in the same fill point & time compared with all previous products, differences become at best the BB2 battle of superior fluid handling efficiency and lower energy but still be part of the work.

Fluid Handling Efficiency

For fluid handling efficiency, the BB2 pump is significantly better. The BB2 pump also boasts a verified hydraulic optimum efficiency point of up to 90.5%, several percentage points above that achieved in the market as a whole. This improvement helps lower operational costs; an aspect that can be a game-changer for businesses unable to withstand high profits while keeping low expenses. While the BB1 pump does compare relatively well, its efficiency might not be up to supporting very badass high-volume type applications.

Power Consumption

Regarding power consumption, the BB2 pump was designed to use energy more efficiently. Brewt’s design is optimized to provide minimal resistance to fluid motion and therefore requires less power to operate which reduces energy bills for enterprises. On the other hand, the BB1 pump which is also a reliable pump but due to its standard shape may not be able to get energy efficiency levels.

This article Right here we introduced Several proprietary products for you We are available in Longgang If you’re someone looking for a way to pump efficiently, this is the place to look- An impressive array of products that meet most of your operational needs are ready. Boasting state-of-the-art engineering, their BB2 efficient centrifugal pump is built for applications with brutal fluids such as crude oil and chemical processes. In close cooperation with well-known universities such as Shandong University, Longgang has formed a high-level design team of pumps and continued to innovate in pump design.

As well as the BB2, Longgang has a focus on pumps that are resistant to highly corrosive material allowing you greater choice for harsh environments. Longgang holds ISO9001:2008 and API certifications, having not only always focused on the quality of its products but also cultivating an active culture of integrity and efficiency to maintain long-term relationships with its clients alike. Longgang is certified to both ISO9001:2008 and API standards, and it values integrity and efficiency to build a long-term client relationship.

The products of Longgang, including the BB2 pump and a series of other special pumps, are popular in well-known enterprises or unit leaders among modern trades and even more have been praised by China National Petroleum Corporation (CNPC) and Sinopec. This reflects the broad application of Longgang products including offshore drilling equipment and the coal chemical industry. Longgange can produce products ranging from offshore drilling to the coal chemical industry etc.

When weighing your next pumping solution, the unique benefits of the BB2 pump over the BB1 can help direct you toward a selection that supports plant performance while accommodating challenges in your sector. The BB2 pump of Longgang allows you to live and nourish your operations even if you have to deal with environments that challenge your systems, but only if you choose wisely.

To summarize, the BB1 and BB2 pumps have their place in industry but with more design innovation, upgraded materials, and higher performance capabilities the BB2 is a serious contender for today’s needs! In short, while the BB1 and BB2 pumps have important roles in industrial applications, it is clear that due to their design characteristics, they are suited to very different service environments and that where applicable the advances concerning features, materials, and performance represented by the BB2 make them a strong contender for modern requirements.

Technological Innovations in the BB2 Pump

The BB2 pump includes various technological advancements that make it more advanced than other pumps for several reasons. With industries changing so does the need for unique, breakthrough solutions to be engineered and hence we welcome the BB2 pump to answer the call. As industries evolve and require more innovative solutions, the BB2 pump delivers an answer to both through intelligent engineering.

Advanced Control Mechanisms

Electric and Hydraulic Integration

The BB2 pump integrates electric and hydraulic control systems to optimize performance in real time. This integration allows for precise monitoring and adjustments, enabling operators to maintain optimal flow rates and reduce energy waste. With the ability to interface with various control systems, the BB2 pump provides a flexible solution that fits seamlessly into diverse operational environments.

Sensor-Based Monitoring Systems

Another technological advancement found in the BB2 pump is its usage of sensor-based monitoring systems. These sensors continuously monitor key parameters, such as pressure, temperature, and flow rate. By providing real-time data, the BB2 pump allows operators to maintain ideal operating conditions, ensuring reliability and extending the pump’s lifespan. Such technology mitigates the risk of unexpected breakdowns, enhancing overall efficiency.

Enhanced Durability and Longevity

Durability is a crucial aspect of pump performance, and the BB2 pump is designed with longevity in mind. Its construction utilizes resistant materials and advanced manufacturing techniques to withstand the rigors of harsh industrial environments.

The BB2 pump’s enhanced durability results from its superior material composition and design, ensuring that it can handle corrosive and abrasive fluids with confidence. Consequently, you can expect fewer maintenance requirements and minimized downtime, contributing to improved productivity and cost-effectiveness in your operations.

Applications and Use Cases

Understanding the range of applications and use cases for the BB1 and BB2 pumps allows for informed decision-making tailored to your specific needs. Each pump has proven its utility, but their applications highlight notable distinctions.

BB1 Pump Typical Applications

The BB1 pump finds its footing in various sectors due to its reliable performance across general pumping applications. Common typical uses include light chemical transport, water circulation, and other moderate-duty tasks. Its robust design serves well in many scenarios, leading to widespread adoption in established industries.

However, as industrial demands increase, the BB1 pump may fall short in applications requiring enhanced efficiency and resilience. While the BB1 remains a viable option for simpler requirements, it may not cater adequately to the evolving needs of competitive and high-capacity operations.

BB2 Pump-Specific Applications

In contrast, the BB2 pump excels in specialized applications, particularly those involving the transportation of crude oil, natural gas processing, and the chemical industry. Its design enhances fluid handling, making it suitable for high-demand circumstances. The BB2 is particularly beneficial for operations requiring the transfer of corrosive materials, thanks to its innovative construction and superior materials.

You can deploy the BB2 pump in offshore drilling operations, where the need for high efficiency and reliability in harsh environments is paramount. The engineering behind the BB2 allows it to maintain peak performance even under extreme conditions, ensuring that your processes remain uninterrupted.

Longgang’s BB2 Pump Offerings

Longgang is a leader in the pump manufacturing sector, offering a diverse range of products, including the cutting-edge BB2 pump. Their commitment to innovation, quality, and performance sets them apart in the industry.

Product Range and Specifications

Longgang’s BB2 product line showcases a variety of pumps tailored to meet different operational needs. The specifications encompass various capacities, designs, and materials, enabling you to select a pump that aligns with your operational requirements. As an expert in the industry, you can appreciate the importance of having tailored solutions at your disposal.

Moreover, the BB2 pumps are designed with high hydraulic efficiency, reflecting Longgang’s commitment to sustainability and energy conservation. By investing in a BB2 pump, you are equipped with technology that promotes lower energy consumption while delivering optimal performance.

Key Features of Longgang’s BB2 Pumps

The key features of Longgang’s BB2 pumps highlight their unique advantages in industrial applications. Among them are the advanced control mechanisms that enhance fluid monitoring and operational efficiency. Coupled with durable construction, these pumps ensure longevity and reliability under demanding conditions.

In conclusion, understanding the unique characteristics that distinguish the BB2 pump from its predecessor, the BB1 pump, grants you insights into elevating your operational efficiency. The BB2’s advanced technologies and robust applications make it an invaluable asset, and Longgang’s dedication to quality ensures you receive highly dependable solutions tailored to the challenges of modern industrial environments.