Centrifugal pumps play a significant role in the industrial and household sectors by making fluid transfer efficient and smooth. It is quite essential to distinguish between the pump types while fluid handling for any of your applications. This blog provides an overview of three categories depending on the direction of flow, namely pumps, axial pumps and mixed flow pumps.

Introduction to Centrifugal Pumps

Before discussing the types of centrifugal pumps available today, let us take the concept and operation of a centrifugal pump itself to lay a proper foundation of understanding first, which shall also help in distinguishing their differences effectively for the better comprehension of how each type functions and suits different applications.

What is a Centrifugal Pump?

A centrifugal pump is a device made to circulate liquids; it is a converter of energy into force, effectively using an impeller that increases the speed and pressure of the fluid so as to permit its transportation with ease and fluidity through the pipes. Therefore, these pumps are used in many different applications.

How do Centrifugal Pumps Work?

In a pump systems configuration, a shaft connects either a single impeller or multiple impellers that spin around engagingly. As the impeller spins around the shaft’s rotation, it draws in fluid through the pump’s inlet and moves it forward using its spinning blades to accelerate its velocity. Subsequently, the fluid is channeled towards a diffuser casing or pump volute where its high speed is converted into pressure levels. The pressurized fluid is then ready to be transported to its designated destination. Part of the motor’s power converts into the fluid’s motion energy while another portion becomes stored as pressure energy.

Types of Centrifugal Pumps Based on Flow

Depending on the design of the impeller and features of the casing as well as how the shaft is positioned and the total number of stages they contain, they can be classified as axial and mixed flow pumps.

Centrifugal pumps flow function by expelling liquid at an angle relative to the pump shaft’s orientation and are frequently utilized for applications that demand high pressure but low flow rates.

How Radial Flow Pumps Function

Flow pumps work by guiding the fluid into the impeller and then directing it out in a flow pattern. The unique design enables the energy from moving towards the edges of the impeller to convert into pressure energy.

Applications of Radial Flow Pumps

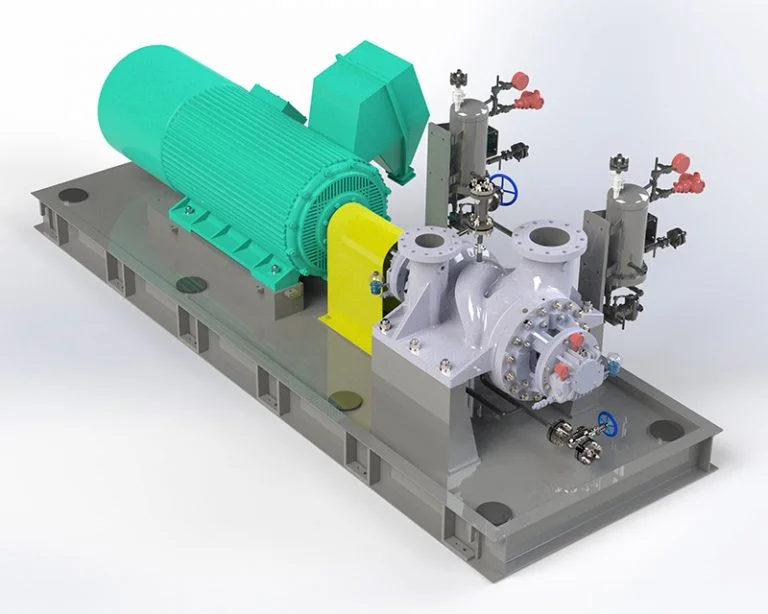

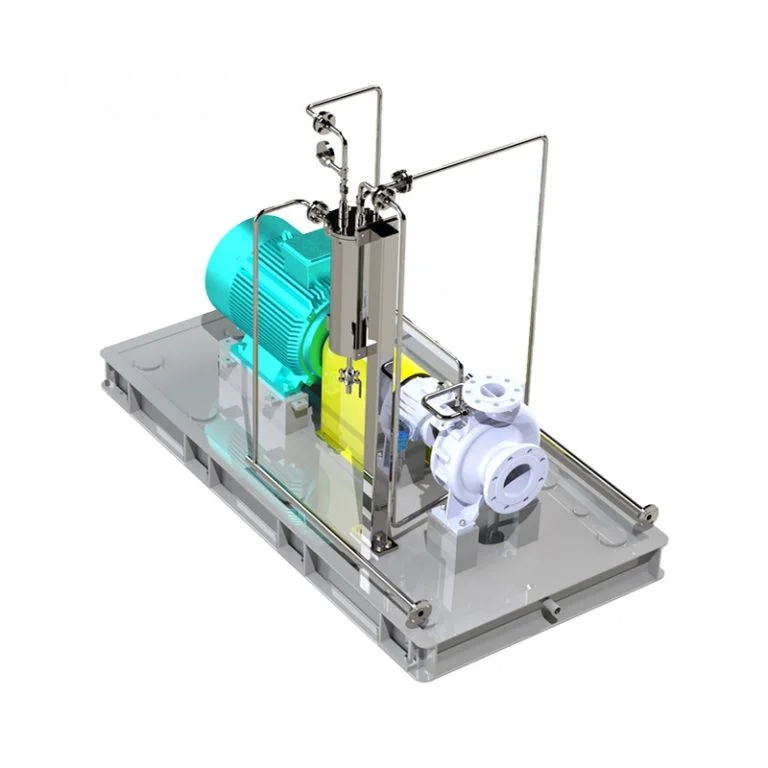

Radial flow pumps play a role in multiple industrial and commercial environments, such as the oil and gas sector where they are commonly found in API pumps as well as in chemical processing and water supply systems for maintaining moderate flow rates and high-pressure requirements because of their sturdy build and capability to withstand greater pressures.

Axial Flow Centrifugal Pumps

If your task involves transferring volumes without needing a significant boost in pressure requirements, consider choosing axial flow pumps.

How Axial Flow Pumps Function

Axial flow pumps use impeller blades to generate a force that imparts speed to the fluid as it flows alongside the pump shaft—a design that excels at transporting substantial amounts of fluid with minimal pressure requirements. It’s akin to envisioning how a propeller moves water in words.

Applications of Axial Flow Pumps

Axial flow pumps are frequently used in situations such as flood control and irrigation of agricultural areas or extensive water distribution systems because of their ability to efficiently handle substantial liquid volumes.

Mixed Flow Centrifugal Pumps

Mixed flow pumps combine features from axial flow layouts to achieve a ground between the two design types, offering a choice that provides sufficient flow rates and moderate pressure levels, making them versatile for various uses.

How Mixed Flow Pumps Function

Mixed flow pumps combine elements of axial and radial-pump designs to increase flow rates beyond those of pumps and maintain moderate pressure levels akin to axial flow pumps by enabling fluid movement in both axial and radial directions as it passes through the impeller.

Applications of Mixed Flow Pumps

Mixed flow pumps are very adaptable and widely used in water supply systems and agricultural irrigation setups as well as for circulating cooling water efficiently within a system. They are commonly used in applications that require a combination of flow rates and moderate head capacities.These pumps are common in general uses because they can be used and adjusted easily for any need.

Selecting the right centrifugal pump

A centrifugal pump selection is highly crucial in order to assure efficient and reliable performance of your fluid handling system.

Factors to Consider

When selecting a pump for your needs, it’s important to consider crucial factors.

Flow Rate

This refers to the quantity of fluid moved by the pump in a specified period. Flow rates applied dictate the size of the pump as bigger pumps are needed for higher flow rates.

Head Pressure

This is the amount of pressure the pump can create to move fluid from one point to another. You should choose a pump that can produce the required head pressure to move the fluid effectively throughout your system.

Fluid Viscosity

Viscosity measures how much of a fluid’s resistance to flow or its “thickness” will have an effect on pump performance. Fluids with high viscosity require pumps having bigger impellers and slower speeds and might best be handled by positive displacement pumps rather than centrifugal pumps.

Pump Material

Material selected for the pump should be compatible with the fluid that is to be pumped so as not to suffer from corrosion or abrasion. Various fluids can be pumped by different materials. Chemical compatibility charts can be referred to determine the appropriate material.

Reliable Supplier

When selecting a supplier or manufacturer, one should observe the level of expertise and products quality. As an example, Yantai Longgang Pump Industry Co., Ltd. specializes in the manufacturing of pumps within the industry that meets the standards by API and non-API for areas such as oil and petrochemicals in addition to the water treatment and coal chemical sectors. The company upholds strict quality standards with a focus on efficiency and reliability, employing advanced hydraulic design tools to suit individual customer requirements.

FAQs

Here are a few questions with common answers which will better facilitate your understanding about pumps.

1. What are the main differences between radial, axial, and mixed flow pumps?

Radial flow pumps produce high pressure at low flow rates by throwing fluid perpendicular to the shaft. Axial flow pumps are appropriate for high flow rates at low pressure with fluid moving parallel to the shaft. Mixed flow pumps take both of the features mentioned, offering moderate flow rates and pressure.

2. Centrifugal pumps can work with viscous liquids?

Yes. Centrifugal pumps can accommodate low to moderate viscosity types.

3. In cases where fluid has a viscosity higher than 200cP what action should I undertake?

Consulting with the pump manufacturer is advisable. While for fluids with viscosities over 500 cP, positive displacement pumps are often more suitable.