API pumps are created to manage a variety of hydrocarbons and other liquids following the guidelines set by the American Petroleum Institute (API). These pumps come in types like end suction and vertical turbine models and are widely utilized in the petroleum sector as well as in the petrochemical and natural gas industries. The API has over 500 standards and recommended practices that cover different aspects of industry. This blog will guide you to deeply know API pumps.

What Is API Pumps

API pumps are manufactured following the specifications outlined by API standards to ensure the reliable design and construction of pumps used in the oil and gas sector. These pumps are specifically engineered to transport fluids under pressures and temperatures while also being capable of handling various hydrocarbons like crude oil, natural gas, refined fuels and aromatic hydrocarbons. In addition, they can manage hydrocarbon substances such as sulfuric and hydrofluoric acids, caustics and solvents as well as water-related applications including boiler feed, seawater, condensate and fresh water.

Definition and Purpose of API Pumps

API pumps are pumps that follow the guidelines set by the American Petroleum Institute (API). They are tailored for applications in the petroleum industry and related sectors like petrochemicals and natural gas handling to handle fluids safely and efficiently under conditions such as high pressure and temperature requirements.

Types of API Pumps

Different types of API pumps are available to cater to specific applications.

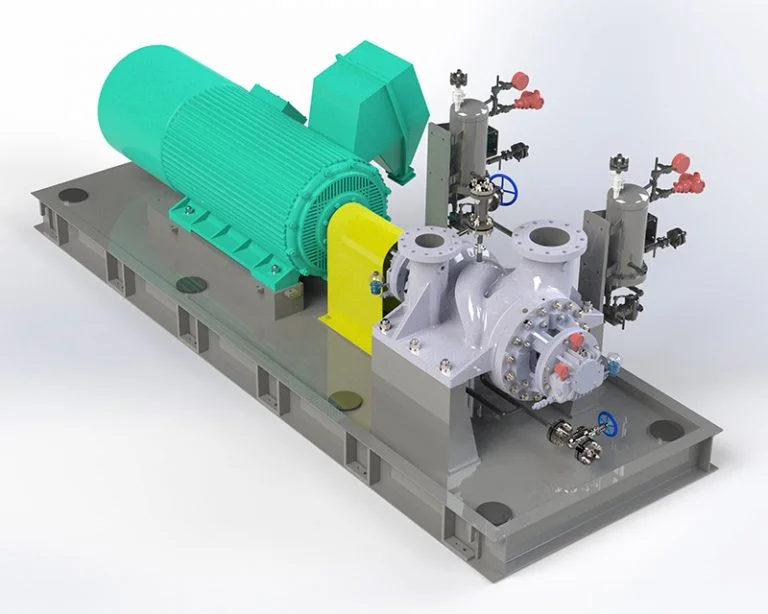

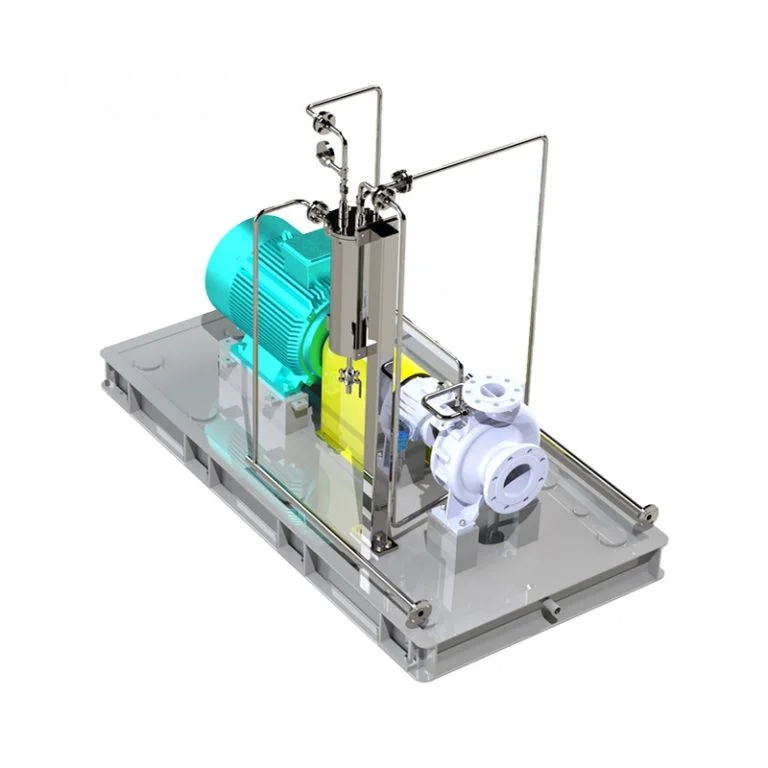

- BB Seriescomprises axially split suction centrifugal pumps, such as the BB17 (Light Aeronautical Duty) utilized for transferring clean fluids or liquids with minimal particle content and the BB23 (Large Bore Diameter) designed for demanding petrochemical processes capable of handling high pressures and temperatures.

- Single-stage cantilever pumps like OH Series (OH LZA and OH LZE versions) are crafted to convey slightly impure fluids in different sectors.

- Vertical suspended single shell pumps such as the VS Series (LDTV model). Vertical suspended bag pumps, like the VS Series (LDT model), are designed for tasks that deal with substances that vaporize easily.

Key Features of API Pumps

API pumps are well known for their construction and adherence to strict regulations.

- Flange Configuration: Conforms to ANSI/DIN/ISO standards for reliable connectivity.

- Mechanical Seals: Designed according to API682 standards to ensure leak prevention.

- Bearing Design: Heavy-duty bearings provide long service life and stability under harsh conditions.

- Hydraulic Efficiency: Advanced hydraulic designs ensure high efficiency and low cavitation margins.

Benefits of Using API Pumps

Pumps within the API category provide advantages that make them a top pick for diverse industrial uses. They are known to deliver reliable performance while meeting the rigorous requirements of their operational settings.

Efficiency and Performance

API pumps are crafted to operate at peak efficiency to enhance energy utilization and lower operational expenses effectively. They are engineered with components and premium materials to deliver reliable pump performance in demanding circumstances while ensuring operational uptime and minimizing the risk of malfunctions.

Reliability and Durability

API pumps are built to last with a focus on durability as a feature in their design architecture. The sturdy shaft construction guarantees functioning even under high speeds and the robust bearings efficiently handle radial forces for reduced noise and vibration levels.

Compliance and Standards

Adherence to standards like ISO9001 and API quality certifications, confirms that these pumps satisfy the needs of the international industry, ensuring their dependability in diverse industrial environments.

Applications of API Pumps in Industries

Pumps from the API are crucial across sectors such as oil and gas exploration and production as well as chemical processing and water treatment operations to uphold efficiency and safety protocols while ensuring reliability in the processes involved.

Oil and Gas Sector

In the oil and gas sector, the use of API pumps is crucial for maintaining operations in drilling rigs and offshore platforms. These pumps are responsible for handling the transportation of high-pressure substances such as oil, natural gas and refined products.API pumps play a role, in pipelines by guaranteeing the smooth flow of fluids even in challenging environments. They are highly valued for their reliability and robustness in supporting the tasks of the industry.

Chemical Processing Industry

In the field of chemical processing, API pumps play a role in managing corrosive substances effectively, offering significant advantages to the industry in terms of efficiency and reliability. The petrochemical multi-stage centrifugal pump developed by the company has earned recognition as a top-tier brand in Shandong, underscoring its performance within this specialized sector.

Water Treatment Facilities

API pumps play a role in water treatment plants, ensuring the smooth transfer of fluids in an efficient manner. They are designed with materials that can resist corrosion, making them well-suited for handling a variety of chemicals commonly used in water treatment procedures.

Choosing the Right API Pump for Your Needs

Choosing the API pump is crucial to maintain efficiency and safety while keeping costs in check. There are aspects to ponder when deciding on a pump model.

Factors to Consider When Selecting an API Pump

Choosing the API pump involves taking into account various factors to make sure it’s the perfect fit for your application needs. Specifically crucial is the type of fluid being pumped – whether it’s a liquid or has impurities present in it like corrosive components or high temperatures – as this will determine the specific pump needed.

Maintenance and Service Requirements

API pumps are designed to last and work reliably over time, but to keep them running smoothly and for a long time, regular maintenance is key. Don’t forget to keep an eye out for wear and tear by giving components, like bearings, seals and impellers. It’ll help prevent any major issues down the line!

Cost Considerations

When selecting an API pump for your needs cost plays a role in considering more than just the initial price tag, it also involves long-term expenses like energy use and maintenance as well as the potential costs of downtime when failures occur.

Professional Supplier

Yantai Longgang Pump Industry Co. Ltd is a provider of API pumps offering comprehensive pump solutions for sectors such as petroleum and petrochemicals as well as coal chemicals among others. They manufacture chemical centrifugal pumps in BB series, OH series and VS series that are highly sought after both domestically and overseas. They place a strong emphasis on self-directed research and development, striving to push forward advancements in pump technology.

Future Trends in API Pump Technology

The realm of API pump technology is constantly progressing with developments and improvements shaping industry practices in a meaningful way.

Innovations and Advancements

The advancement of API pump technology is characterized by innovation to enhance effectiveness and reliability while adhering to environmental standards. The utilization of pumps made from special alloy materials designed to handle highly corrosive substances like anti-dilute sulfuric acid or caustic soda demonstrates significant progress in managing challenging media.

Impact on Industry Practices

Advancements in pump technology for API influence how industries operate by improving efficiency and lessening environmental impact. These new developments are set to make a difference in how industries operate by boosting efficiency and safety while cutting costs and downtime significantly .By incorporating the latest technologies API pumps will continue to be crucial equipment across different sectors.

FAQs

1. How do API pumps differ from ANSI pumps?

High-pressure and high-temperature API pumps are crafted to adhere to API standards for specific applications. Conversely, ANSI pumps are more commonly employed in chemical processing with lower pressure requirements.

2. What is the typical lifespan of an API pump?

When well taken care of and serviced correctly in conditions, API pumps can remain functional for 15 to 20 years or even longer.

3. What are common failure modes in API pumps?

Common issues may arise such as leaks in seals and worn bearings caused by maintenance or operating conditions.