Chemical pumps and industrial pumps have roles in different settings due to variations in their structure and functions. Chemical pumps are tailored to manage fluids securely as they are resistant to corrosive substances. On the other hand industrial pumps are designed for a wide range of fluid applications. This blog delves into the differences in design materials used and performance factors between these pump types offering guidance for selecting the pump, for industrial and chemical scenarios.

What Are Chemical Pumps and Their Unique Features?

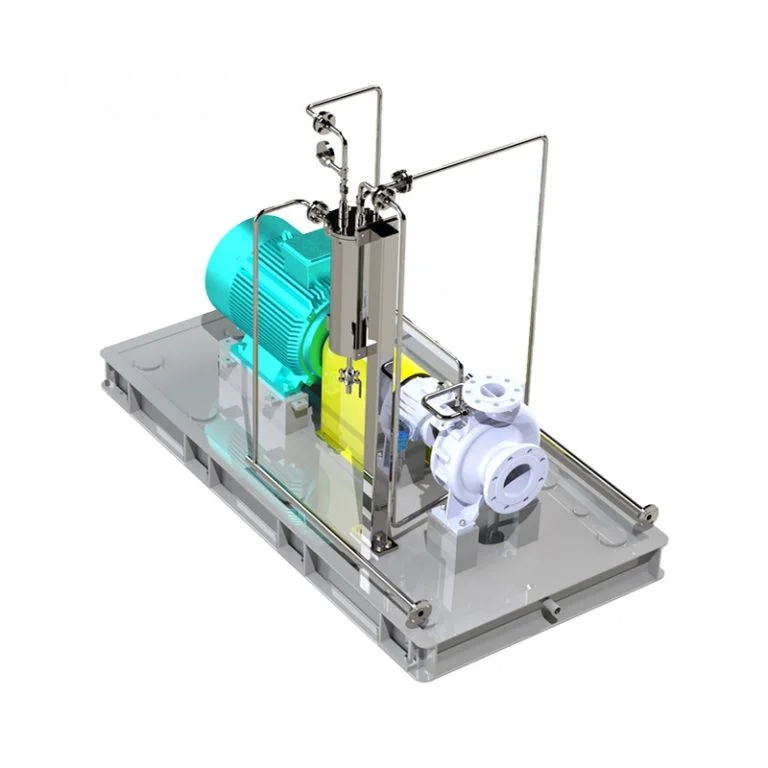

When it comes to working with industrial applications like pumps, design analysis is key to success. Chemical pumps stand out among the crowd because of their focus and design elements that enable them to manage harsh and corrosive liquids effectively and set them apart from other types of industrial pumps.

Definition and Purpose of Chemical Pumps

Chemical pumps are made to move chemicals efficiently, even those that are highly corrosive or dangerous. This essential equipment plays a role in industries like petrochemicals and coal chemicals by handling various substances used in sectors, such as petroleum refining and environmental protection. The distinct materials and design elements of these pumps focus specifically on ensuring the transfer of potentially hazardous fluids.

Materials Used in Chemical Pump Construction

Chemical pumps are crafted from materials specifically selected for their resistance to corrosion and wear and tear situations. The initiative to manufacture pumps from alloy materials highlights the importance of choosing the materials to ensure durability and safety over time.

Sealing Mechanisms in Chemical Pumps

The importance of sealing mechanisms in chemical pumps cannot be overstated as they play a role in handling various fluids safely and preventing potential leaks that may pose risks to safety and the environment. Mechanical seals and magnetic drive seals are among the sealing systems commonly employed for this purpose.

How Do Industrial Pumps Differ from Chemical Pumps?

Chemical pumps are designed with characteristics to handle chemicals securely and effectively, whereas industrial pumps have a wider scope of uses across different industries and sectors. Knowing these distinctions is crucial when choosing the appropriate pump for your requirements.

General Characteristics

Industrial pumps are devices utilized in various industries such as water distribution systems and oil & gas sectors as well as in the production sector at large. They are capable of managing a variety of liquids ranging from water to thick slurries. The focus lies more on versatility than being specialized in one area.

Design Considerations

When creating pumps, the main priorities are to ensure they work efficiently and reliably under different operating conditions.These pump designs typically include bearing systems and volute casings to handle various pressures and temperatures effectively.

Material and Construction Differences

In settings, pumps may not always need the special materials that chemical pumps use, but they still need to be tough enough to handle different types of fluids effectively. The material chosen for these pumps often relies on needs, like how well it can handle temperature variations or resist wear and tear.

Why Is Material Selection Crucial in Pump Design?

Selecting the materials is key when it comes to determining the lifespan and efficiency of a pump as it influences how well the pump can endure exposure to fluids in the long run.

Impact of Fluids on Pump Materials

Different types of liquids can affect the materials used in pumps; some might corrode them, while others could cause erosion or scaling within the pump system itself. Choosing the materials can help reduce these risks by offering protection against potential harm from certain properties of the fluid.

Innovations in Material Technology for Pumps

Progress in material technology has resulted in pump designs that can operate effectively in tough conditions without sacrificing performance or safety standards. Understanding the design variances between chemical pumps and other industrial counterparts as well as the importance of selecting appropriate materials, will enhance your ability to choose the best solution tailored to meet your operational needs in various industry settings.

How Do Safety and Efficiency Compare Between These Pump Types?

When you’re looking at chemical pumps in comparison to industrial pumps, there are a couple of key things to keep in mind: safety and efficiency are crucial factors that need to be taken into account here. Dealing with chemicals requires certain design elements unique to chemical pumps, whereas when it comes to industrial pumps the focus is more about ensuring efficiency across a wide array of uses.

Safety Features in Chemical Pumps

Ensuring safety is crucial when designing chemical pumps as they deal with harmful fluids that require careful handling measures in place to prevent any leaks or containment breaches of dangerous substances they transport securely within them. The size of the sealing cavity meets the standards set forth by API682 to accommodate types of mechanical seals based on specific operational requirements. This practice serves to enhance safety levels by reducing the chances of being exposed to chemicals significantly.

Efficiency Metrics for Industrial Pumps

Industrial pumps are created to work efficiently and deliver performance in various operating conditions by incorporating innovative design elements and durable materials that enhance fluid movement and reduce energy usage.

Yantai Longgang: Reliable Supplier of High-quality Pumps

Yantai Longgang Pump Industry Co., Ltd. is a high-tech company that focuses on producing top-notch pumps for various industries including petroleum and environmental protection. The company offers a variety of centrifugal pumps in its product lineup such as the BB series and OH series to meet industry standards efficiently. The company prioritizes customer satisfaction by providing solutions and technical advice along with standardized production methods to establish itself as a reliable pump supplier globally.

When you opt for Yantai Longgang Pump Industry Co., Ltd., you not only get top-notch products but also enjoy their focus on expertise to provide outstanding service throughout your path to achieving operational excellence.

FAQs

1. What sets pumps apart from positive displacement pumps?

Centrifugal pumps have rotational power to propel liquid efficiently in situations requiring high volume but low-pressure levels.

2. What are the factors that lead to a decrease in pressure or flow in a pump?

Encountered reasons comprise blocked impellers, worn-out seals, air seepage, or incorrect pump sizing.

3. Can pumps manage fluids that contain solids or abrasives effectively?

Yes. Some pumps, such as diaphragms or slurry pumps, are specifically engineered to handle fluids or those with suspended solids within them effectively and efficiently every time you use them in your application area.