Overview of Pumps in Industrial Applications

Defining API Pumps

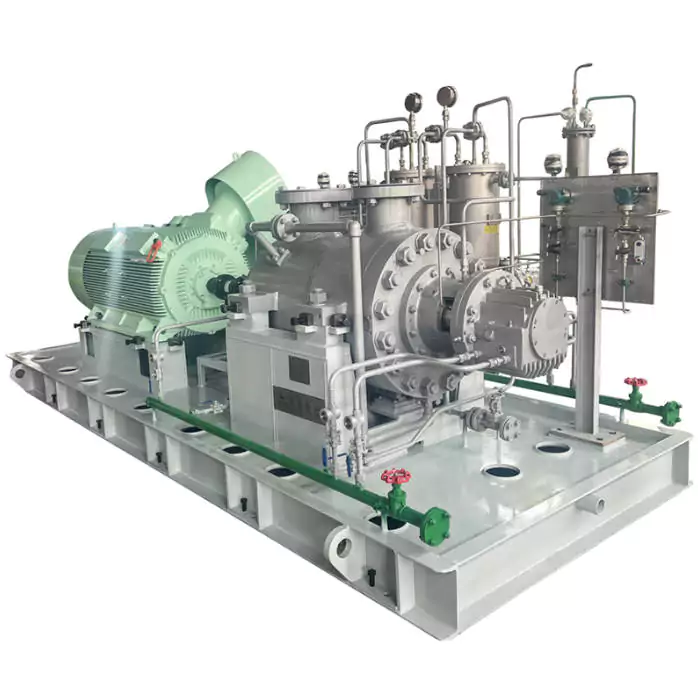

API pumps, specifically defined by the American Petroleum Institute (API), are built to international standards to meet the challenging requirements of the petroleum and petrochemical industries. The API designations, such as API 610 for centrifugal pumps, ensure that these pumps are manufactured and tested under strict operational protocols. Features like mechanical seals, specialized bearings, and corrosion resistance are typical in API pumps, making them highly dependable for high-temperature and high-pressure conditions. The conformity to API standards ensures longevity, safety, and reliability, essential traits for industrial applications where downtime and maintenance can result in significant costs.

Defining Non-API Pumps

Non-API pumps, in contrast, do not have to adhere to stringent industry standards set forth by organizations such as the API. These pumps are generally used in less critical applications, often involving less aggressive fluids. Because of the flexibility in their design and manufacturing processes, non-API pumps may provide a more budget-friendly solution, catering to industries with less demanding requirements. Despite their lower costs, it is essential to recognize that non-API pumps may lack some of the durable features found in API pumps, leading to concerns about their efficiency and longevity under strenuous operating conditions.

Design and Construction Differences

Structural Features of API Pumps

The design and construction of API pumps are characterized by features that ensure long-term reliability and robust performance.

Higher Durability and Heavier Duty Design

API pumps are manufactured with materials and configurations that enhance their durability and performance in extreme conditions. Their designs can often accommodate higher temperature and pressure thresholds than their non-API counterparts. For instance, the construction of their casings, rotor assemblies, and seals is meticulous, ensuring they function effectively in demanding environments found in the oil and gas sector.

Enhanced Temperature and Pressure Handling

API pumps are engineered to handle greater stresses from high temperatures and pressures effectively. They often incorporate advanced sealing technologies that minimize leakage and optimize maintenance cycles, which is vital in applications involving hazardous and corrosive fluids. The engineering considerations taken during the design phase culminate in products that meet the operational needs of industries such as oil and gas, ensuring optimum fluid movement and system integrity.

Structural Features of Non-API Pumps

Non-API pumps, while efficient in their own right, typically lack the heavy-duty features present in API pumps.

General Construction Characteristics

The construction of non-API pumps tends to be simpler, focusing on cost-effectiveness rather than heavy-duty performance. These pumps may utilize lower-grade materials that suffice for particular applications but may not endure as long or operate as efficiently under extreme conditions. Their designs often include basic sealing mechanisms and lack the advanced configurations seen in API pumps.

Application-Specific Designs

While non-API pumps can be customized for certain applications, such designs may not equal the rigorous standards found in API pumps. They are commonly employed in less severe conditions where safety and performance under high stress are not as critical. This flexibility makes non-API pumps appealing to sectors that do not require the enhanced specifications that accompany API-certified pumps.

Yantai Longgang Pump Industry Co., Ltd. offers an extensive range of pumps, including the LCD(BB3) horizontal split multi-stage pump designed for various industrial applications. The LCD(BB3) adheres to stringent standards, focusing on high efficiency and reliability. With its unique structural features, this pump efficiently handles cooling and heating fluids, promising low maintenance and long service life due to its advanced mechanical seals and lubrication mechanisms. The design is ideal for transporting various easily vaporized media, positioning it as a preferred choice in the petrochemical and industrial sectors. Its compatibility with auxiliary monitoring systems further enhances operational safety, ensuring it stands out in comparison to non-API pumps.

Performance Capabilities

Reliability Under High-Stress Conditions: API Pumps

API pumps are built with a focus on reliability, particularly under high-stress conditions that are often encountered in industries such as oil and gas. These pumps are designed to operate effectively at elevated temperatures and pressures while minimizing the risk of failure. A significant aspect of API pumps is their adherence to the specifications outlined in API 610, which emphasizes rigorous testing and quality standards. This results in a robust design that often incorporates heavy-duty materials and advanced sealing technologies to prevent leaks and extend the life of the pump. Furthermore, API pumps are often equipped with multi-point support structures for bearings, which help in distributing loads evenly and reducing wear over time. This intricate design ensures that API pumps can sustain continuous operation under the most challenging industrial environments, thereby significantly reducing downtime and maintenance costs.

Performance in Standard Industrial Uses: Non-API Pumps

While API pumps excel in high-stress scenarios, non-API pumps are designed primarily for standard industrial applications where conditions are less severe. These pumps offer a reliable solution for a variety of less demanding processes, which can include water transfer or the movement of basic industrial fluids. Non-API pumps typically feature simpler designs with fewer components, which can lead to easier maintenance and lower operational costs. However, it is important to acknowledge that these pumps may not perform as efficiently under fluctuating temperature and pressure conditions. Their materials may also not be suited for transporting corrosive or hazardous fluids, which limits their application scope. Consequently, while non-API pumps are suitable for various standard industrial uses, they may not provide the same level of performance and reliability that API pumps offer in more demanding circumstances.

Application Suitability

When to Choose API Pumps

High Pressure and Temperature Applications

In applications that involve high pressure and temperature, choosing API pumps is often essential. The design of these pumps incorporates advanced engineering that allows them to withstand extreme operational conditions without compromising performance. They are specifically configured to handle the stresses associated with the transportation of fluids in refineries, petrochemical plants, and other high-demand industries. Moreover, API pumps typically feature enhanced cooling and sealing mechanisms, which help maintain operational integrity even in extreme environments. With the potential costs associated with pump failure being substantial, the reliability and durability of API pumps provide peace of mind for operations concerned with product safety and continuity.

Emission Control Requirements

API pumps can also be pivotal in applications where emission control is a significant concern. Their sophisticated sealing technologies and construction standards are geared toward minimizing leakage of potentially hazardous fluids, thus complying with stringent environmental regulations. This is particularly beneficial in the petrochemical industry, where regulations around volatile organic compounds (VOCs) and other emissions are increasingly strict. The investment in API pumps not only facilitates compliance with environmental standards but also contributes to a company’s overall sustainability efforts. As such, for industries facing regulatory pressures regarding emissions, API pumps offer a strategic advantage.

When to Choose Non-API Pumps

Cost Considerations and Budget Constraints

Non-API pumps can be the preferred choice when cost-effectiveness is a primary concern. These pumps typically incur lower acquisition costs and benefit from simpler maintenance procedures, making them attractive for projects with tight budgets. They can be sufficient for applications that do not require the robust features found in API pumps and can operate continuously without major variability in conditions. For industries with limited budgets who require reliable fluid handling solutions for general operations, opting for non-API pumps can often lead to savings without significant compromises on performance. However, careful consideration of the application’s requirements is essential to ensure that the chosen pump can meet the necessary operational standards.

Suitable for Less Demanding Applications

Non-API pumps shine in applications where the conditions are not excessively demanding or where fluids being transported do not present chemical or environmental threats. These might include general water transfer, cooling, or situations where the fluid characteristics do not necessitate the advanced features of an API pump. In such conditions, non-API pumps provide an adequate solution while maintaining efficiency and user satisfaction. Furthermore, the adaptability of non-API pumps can cater to a range of industries as long as the requirements align with their performance capabilities, providing a practical choice for non-critical applications.

Yantai Longgang Pump Industry Co., Ltd. excels in providing high-quality pumps tailored to meet both API and non-API standards. Their LCD(BB3) horizontal split multi-stage pump is a prime example of a product designed for efficiency and reliability. The pump not only handles high pressures but also incorporates advanced technology for temperature management, making it suitable for various industrial applications. Its structural features allow for easy maintenance and a long service life, positioning it as a strong competitor in both API and non-API markets. As a result, Yantai Longgang’s offerings ensure functionality across different sectors, fulfilling both performance and budgetary requirements effectively.

Maintenance and Operation Costs

Long-term Investment Considerations for API Pumps

When evaluating long-term investment considerations for API pumps, it is essential to recognize that they may require higher initial capital expenditure but often translate to significant cost savings over time. The construction quality and adherence to API standards result in a longer service life, reduced maintenance needs, and improved operational efficiency. Moreover, their ability to function reliably under demanding conditions decreases the likelihood of unexpected downtime, which can yield substantial economic advantages. Over time, these operational benefits can justify the investment in API pumps, especially in industries where reliability and safety are paramount.

Additionally, API pumps typically incorporate advanced monitoring systems and components designed for longevity, further enhancing their cost-effectiveness. By reducing the frequency and severity of maintenance tasks, companies can keep their operational costs in check. The integration of innovative technologies, such as improved sealing systems and bearing designs, not only enhances performance but also contributes to their durability, leading to lower costs associated with repairs and replacements over the pump’s lifecycle.

Cost Efficiency of Non-API Pumps

Cost efficiency regarding non-API pumps is often linked to their initial low purchase prices and simpler designs. These pumps are typically less expensive to acquire, making them an appealing option for projects with limited budgets. However, while non-API pumps exhibit lower upfront costs, it is crucial to consider the potential long-term costs associated with their use. Due to their simplified construction and lower-grade materials, non-API pumps may experience higher wear and tear, leading to increased maintenance needs and a shorter lifespan compared to API pumps.

In practical application, the cost efficiency of non-API pumps can manifest through reduced operational expenses but may not entirely shield users from longer-term financial implications. Industries that rely on non-API pumps must factor in the potential need for more frequent replacements or repairs, which can accumulate over time. As such, while non-API pumps may provide attractive short-term savings, companies must carefully evaluate the trade-offs in reliability and longevity to ensure they meet overall operational efficiency goals.

In summary, the choice between API and non-API pumps should be guided by a comprehensive analysis of cost implications, operational needs, and long-term investment strategy. Yantai Longgang Pump Industry Co., Ltd.’s LCD(BB3) horizontal split multi-stage pump highlights the balance between performance and maintenance efficiency, showcasing the important attributes of both API and non-API pumps for various industrial scenarios. The maintenance and operation costs associated with pumps should align with an organization’s goals in achieving maximal uptime and service reliability while addressing budgetary constraints effectively.