Understanding Centrifugal pumps

Centrifugal pumps are essential devices used across multiple industries for fluid transportation by transforming rotational kinetic energy into hydrodynamic energy. The main operation of a centrifugal pump involves a rotating impeller that speeds up the fluid, propelling it through the pump’s discharge. Commonly driven by an electric motor, these pumps are celebrated for their straightforwardness and efficiency in moving fluids.

Basic Functionality

At its core, the centrifugal pump uses centrifugal force to move liquid. As the impeller rotates inside the casing, it throws the fluid outwards to the periphery, increasing its velocity and pressure. The fluid then moves into the pump discharge at a higher energy level. This process ensures a continuous flow of fluid through the pump which is vital for many operational scenarios in various industry sectors.

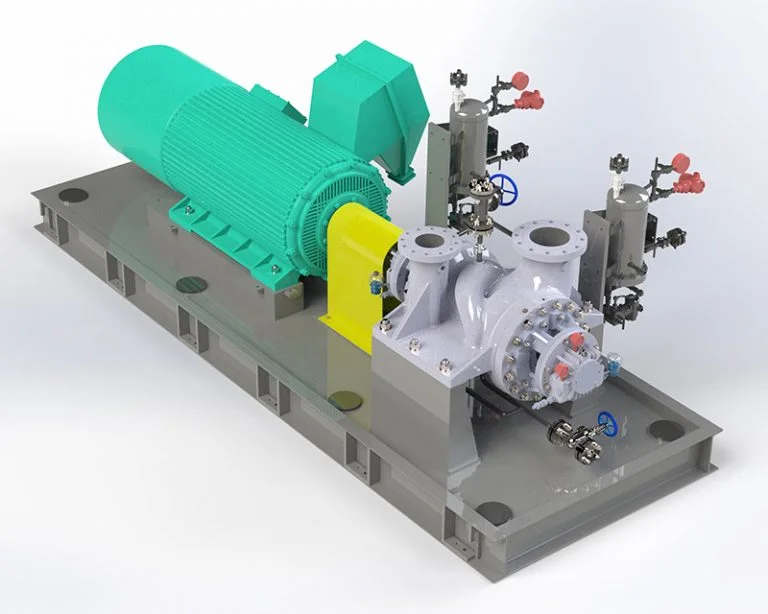

Key Components

The main components of a centrifugal pump include the impeller, casing, shaft, bearings, and seals. The impeller, a key component, comes in different designs tailored to specific applications, directly influencing the pump’s performance. The casing efficiently directs the fluid flow and houses the impeller. Other components like shafts, bearings, and seals play crucial roles in maintaining the alignment, stability, and operational efficiency of the pump.

Yantai Longgang Pump Industry Co., Ltd. was established in May 2001. It is located in the Yantai National High-tech Industrial Park. The company is recognized as a “high-tech enterprise,” “Contract-abiding and trustworthy enterprise,” and “Shandong Province specialized and innovative enterprise.” It owns the “Yantai Municipal Enterprise Technology Center” and has been awarded the “China Machinery Industry Science and Technology Progress First Prize” and the “Zhejiang Province Science and Technology Progress Award.” It has also participated in the formulation of national standards for the pump industry. The company’s petrochemical multi-stage centrifugal pump was honored as the “Shandong Excellent Brand” in 2020 and was selected as a “Shandong Gazelle Enterprise” in December 2020.

The company mainly produces BB series, OH series, VS series chemical centrifugal pumps. The products are widely used in various industries such as petroleum and petrochemical, coal chemical industry, basic chemical industry, environmental protection, and water treatment. The products highly welcomed in domestic and abroad.

Yantai Longgang Pump Industry is a qualified supplier of CNPC, Sinopec, and CNOOC etc. It provides mature solutions for pumps in petrochemical equipment and provides key pumps for many domestic installations and applications such as tens of millions of tons of oil refining and millions of tons of ethylene.for coal chemical industry, we are providing a large number of key station pumps for coal gasification, coal liguefaction, coal to methanol, coal to dimethyl ether, coal to olefins and other devices.

Applications in Various Industries

Centrifugal pumps find significant application across diverse industries due to their versatility and efficiency. They are extensively used in water supply systems, wastewater treatment plants, chemical manufacturing, oil and gas production, and food processing industries. Their ability to handle various types of fluids under different conditions underscores their critical importance in industrial operations. These pumps support the operational infrastructure of industries by ensuring a seamless and robust movement of fluids.

Determining Your Pump Requirements

Analyzing System Needs

To determine the best centrifugal pump for your application, begin with a comprehensive assessment of the system’s requirements. Take into account aspects like the type of fluid being pumped, the necessary flow rate, the pressure conditions, and the particular needs of the application. By understanding these parameters, you can navigate the selection process more effectively, ensuring that the pump will operate efficiently and reliably in its designated function.

Flow Rate Considerations

Flow rate is a fundamental parameter in sizing a centrifugal pump. It represents the volume of fluid that needs to be moved over a specified period. Accurate determination of the required flow rate ensures that the pump can handle the demand without overloading or inefficient operation. Factors such as system capacity, operational peaks, and fluid characteristics should be closely examined to determine the appropriate flow rate setting for optimal pump performance.

Total Dynamic Head (TDH) Calculation

Calculating the Total Dynamic Head (TDH) is crucial in pumping systems design. TDH represents the total energy required by the pump to move the fluid through the system. It comprises the static head, friction losses in pipelines, and pressure head. Accurately calculating TDH ensures that the selected centrifugal pump can overcome all resistances and deliver the desired flow rate. This step is vital for ensuring the longevity and effectiveness of the pump in its working environment.

Sizing a Centrifugal pump

Importance of Impeller Diameter

The impeller diameter significantly influences the performance of a centrifugal pump. Larger diameters typically increase the pump’s flow rate and head, while smaller diameters decrease them. Selecting an appropriate impeller diameter to match the system requirements is essential for efficient operation. It directly affects the pump’s capacity to handle specific fluid dynamics and operational conditions.

Impact on Performance

The size of the impeller plays a crucial role in determining the pump’s performance. An appropriately sized impeller guarantees that the pump functions at its optimal efficiency point (BEP), thus avoiding problems such as cavitation and undue wear. Recognizing the performance traits linked to the impeller diameter is essential for optimizing the pump for its specific application, ensuring consistent and efficient fluid movement.

Adjusting for Efficiency

Efficiency adjustments may involve trimming the impeller or selecting a different model within the pump series. This fine-tuning is necessary to align the pump’s performance characteristics with the specific application needs, ensuring energy-efficient operation. Adjusting the impeller size correctly helps in reducing operational costs and extending the pump’s lifespan.

Motor Power Requirements

Assessing the motor power requirements is a critical aspect of sizing a centrifugal pump. The motor needs sufficient power to drive the pump at the necessary speed to achieve the desired flow rate and head. Overpowering or underpowering can lead to inefficiencies or equipment damage. Therefore, a careful balance must be struck to ensure the motor’s power is adequately matched to the pump’s demands.

Selecting the Right Material

Factors Affecting Material Choice

Selecting the right material for a centrifugal pump’s construction is influenced by several factors, including chemical compatibility and temperature resilience. The material must withstand the operational environment without degrading, which ensures long-term reliability and performance.

Chemical Compatibility

Depending on the type of fluid being pumped, it is essential for the material to show compatibility in order to prevent issues such as corrosion, erosion, or chemical reactions. For example, pumps utilized in chemical processing need materials that can withstand aggressive chemicals to avoid harmful degradation.

Temperature Resilience

Temperature resilience is another key consideration when selecting pump materials. High or low temperature applications necessitate materials that maintain their structural integrity under extreme thermal conditions. Using materials with appropriate temperature resilience ensures that the pump operates safely and efficiently, avoiding failures due to thermal stresses.

Commonly Used Materials

Common materials used in the construction of centrifugal pumps include stainless steel, cast iron, bronze, and various high-performance alloys. Stainless steel is particularly favored for its corrosion resistance and durability, making it suitable for a wide range of applications. Cast iron offers cost-effectiveness for less demanding environments, while bronze and specialized alloys are often selected for their enhanced mechanical properties and resistance to wear and corrosion.

Evaluating Efficiency and Cost-Effectiveness

Energy Consumption Analysis

When evaluating the efficiency and cost-effectiveness of a centrifugal pump, an in-depth energy consumption analysis is crucial. This involves assessing the power usage over time to identify opportunities for energy savings. Pumps that operate within their Best Efficiency Point (BEP) tend to consume less energy and yield lower operational costs. Furthermore, analyzing peak and off-peak performance can unveil periods of energy inefficiency that could be optimized with better alignment of operational schedules and energy usage patterns.

Maintenance and Lifecycle Costs

Another critical factor to consider is the maintenance and lifecycle costs associated with the centrifugal pump. Regular maintenance, although crucial for maintaining optimal performance, results in ongoing expenses that must be included in the overall cost evaluation. In addition to routine inspections and part replacements, it is essential to anticipate the pump’s lifespan and possible downtime. Selecting materials and designs that reduce wear and extend the pump’s operational life can lead to considerable cost savings over time. Understanding these elements helps balance initial investment with long-term savings, ensuring a cost-effective solution.

Installation and Operational Practices

Proper Alignment and Setup

For a centrifugal pump to function effectively, proper alignment and setup during installation are paramount. Misalignment can lead to increased wear and tear on components, reduced efficiency, and potential failures. Using precise alignment tools and techniques ensures that the motor and pump shaft are correctly aligned, reducing mechanical losses. Additionally, the setup must ensure a stable foundation free from vibrations, which can detrimentally affect pump performance. Adhering to manufacturer guidelines and industry standards during the installation phase ensures optimal operational efficiency and longevity.

Regular Monitoring and Maintenance

Regular monitoring and maintenance are essential for sustaining the performance and reliability of a centrifugal pump. Routine inspections should focus on detecting signs of wear, leaks, and vibrations that could indicate underlying issues. Utilizing monitoring tools such as vibration analysis and thermal imaging can help identify problems before they escalate into costly repairs or downtime. Preventive maintenance, including lubricating bearings and replacing worn-out seals, prolongs the pump’s lifecycle and maintains efficient operation. Establishing a structured maintenance schedule ensures that the pump continues to perform optimally throughout its service life.

Understanding Industry Standards and Certifications

Compliance Requirements

Compliance with industry standards and certifications is crucial for ensuring that a centrifugal pump meets the requisite safety and performance criteria. Standards such as those set by the Hydraulic Institute (HI), American National Standards Institute (ANSI), and International Organization for Standardization (ISO) provide guidelines on design, testing, and performance evaluation. Adhering to these standards ensures that the pump operates safely under prescribed conditions and meets the necessary regulatory requirements. Compliance also facilitates seamless integration into existing systems, as the pump aligns with widely recognized performance benchmarks.

Ensuring Safety and Reliability

Ensuring safety and reliability is crucial in the deployment of centrifugal pumps. This requires thorough testing and certification to validate the pump’s performance under different operational conditions. Features like fail-safe mechanisms, pressure relief systems, and durable construction materials enhance the overall safety of the pump. Regular audits and re-certifications help maintain the pump’s reliability standards throughout its service life. Prioritizing safety and reliability not only protects industrial systems’ operational integrity but also ensures the safety of personnel and environmental health.

In conclusion, properly sizing and selecting a centrifugal pump requires a comprehensive evaluation of your specific application needs. Carefully analyzing system requirements, efficiency parameters, and compliance with industry standards ensures a harmonious balance of performance, cost-effectiveness, and reliability. With a well-selected and maintained centrifugal pump, industries can achieve optimized fluid movement, reduced operational costs, and enhanced safety and reliability.

In the discourse of industrial pumping systems, particularly within the chemical processing sector, it is imperative to discern the differences between centrifugal pumps and positive displacement pumps. As a chemistry professor, I find it essential to elucidate these distinctions to my students, especially when introducing the exemplary work of Yantai Longgang Pump Industry Co., Ltd.

Centrifugal pumps, such as those manufactured by Yantai Longgang, operate on the principle of imparting velocity to the fluid, which is then converted into flow. These pumps are characterized by a rotating impeller within a casing, which accelerates the fluid outward from the pump’s center to its periphery, and then into the discharge piping system. The flow rate of these pumps is influenced by the system pressure, making them particularly suitable for applications where a variable flow is required.

Yantai Longgang Pump Industry Co., Ltd. specializes in the production of centrifugal pumps that adhere to the rigorous API 610 standard, ensuring their suitability for high-pressure, high-temperature applications often encountered in chemical processing. The company’s centrifugal pumps are designed to handle a variety of chemical substances with efficiency and reliability, while also providing the flexibility needed to adapt to changing system conditions.

The company focuses on technological upgrading and independent research and development. In recent years, it has continuously introduced high-end pump design talents to form a technical team and cooperated with Shandong University, Zhejiang Sci-Tech University, Yantai University, and other universities to carry out industry-university-research cooperation for the continuous development of new products. In addition to chemical pumps made of ordinary anti-corrosion materials, the company has successively developed special alloy material pumps such as anti-dilute sulfuric acid, hydrochloric acid, concentrated sulfuric acid, caustic soda, and other highly corrosive super-low carbon duplex stainless steel pumps. The independently developed BB2 efficient centrifugal pump is mainly used in crude oil transportation, coal chemical industry, natural gas processing, offshore drilling equipment, and other industrial processes. The verified hydraulic optimum efficiency point reaches 90.5%, which is 3.5% higher than the national first-level energy efficiency.