Understanding the Basics of single-stage centrifugal Pumps

Definition and Key Characteristics

The single-stage centrifugal pump is a type of pump that uses a spinning impeller to boost both the pressure and volume of a liquid as it moves through the system. It works by transforming energy from a motor into energy efficiently. This pump features one impeller and volute that help manage flow rates but produce greater pressure. Known for their structure and effective operation, in handling liquids with low viscosity. Centrifugal pumps that operate in a stage find use across different scenarios from providing water to being essential, in chemical processing tasks.

How Single-Stage Centrifugal Pumps Work

The process of starting up a stage centrifugal pump kicks off, with the motor driving the impeller to spin quickly. In this spinning motion, the impeller transfers kinetic energy to the liquid resulting in its movement towards the outlet, for discharge. Upon entering the impeller the liquid gains speed and this speed translates into pressure as it flows into the volute casing. The centrifugal force produced by the impeller empowers the liquid to surpass any hindrances in the discharge line enabling effective transfer of fluids. This particular design guarantees that the pump functions, across a variety of operating conditions.

Common Applications in Various Industries

Stage centrifugal pumps are widely used in industries because of their flexibility and versatility, in different applications. They are commonly seen in water supply and irrigation systems where they efficiently move water to destinations. In the chemical processing sector, such pumps are responsible for handling liquids that contain minute particles or are slightly corrosive. Stage centrifugal pumps also play a role in industries such as power generation, food processing, and HVAC systems where they help effectively transport fluids. Their ability to perform consistently under circumstances has made them a popular option, for a wide range of uses.

Longgang’s Innovations in Single-Stage Centrifugal Pumps

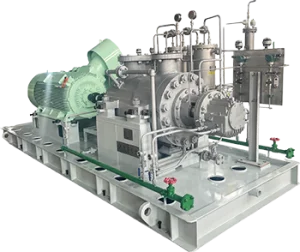

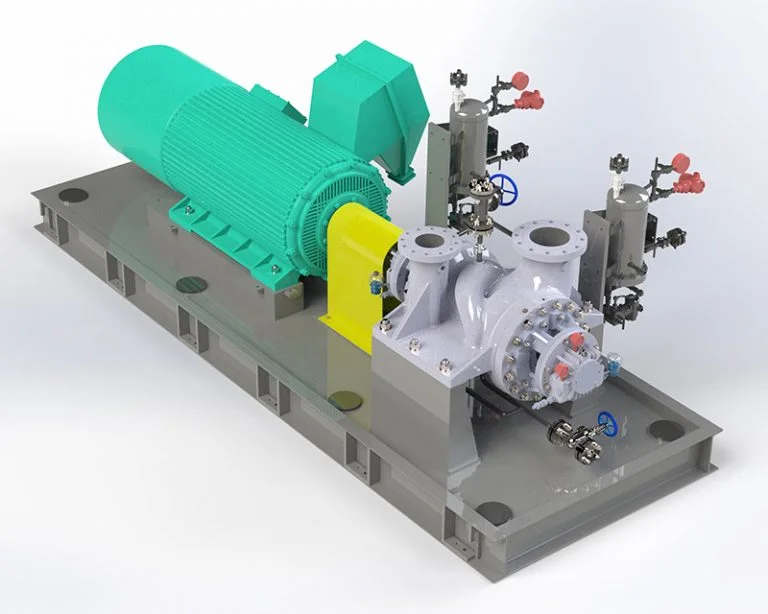

Overview of Longgang’s Product Line

Longgang has become a figure, in the production of notch single-stage centrifugal pumps by focusing on innovation and utilizing cutting-edge technology to enhance performance and dependability in their pump range offerings for various applications such as the petrochemical and industrial sectors with models, like BB1 and BB2 series pumps.

Distinguishing Features of Longgang’s Pumps

Longgangs stage centrifugal pumps stand out due, to characteristics that improve their efficiency significantly. These pumps feature a self-balancing axial force structure that diminishes vibrations and extends the lifespan of the machinery. The unique tongue design plays a role in reducing pressure fluctuations and contributes to smooth and steady operation. Moreover, the incorporation of materials and cutting-edge manufacturing techniques guarantee that these pumps maintain their effectiveness and dependability, in challenging operating conditions. Longgang pumps also provide maintenance solutions that enable disassembly for inspection and repair, without prolonged periods of inactivity.

Performance and Efficiency Metrics

Longgangs stage centrifugal pumps are designed to deliver top-notch efficiency and performance qualities with a focus, on energy efficiency and impressive output levels. Their pumps utilize a design that ensures reliable operation even in fluctuating conditions like cavitation. Additionally, the integration of bearing structures compliant with the API610 standard enhances the longevity and dependability of Longgangs products. Prioritizing innovation the company consistently strives to improve the effectiveness of its pumps to cater to the changing requirements, across industries.

Making an Informed Decision with Longgang

Importance of Customization and OEM Services

Tailoring plays a role, in the production of stage centrifugal pumps since various applications frequently demand specific attributes or standards to be met. Longgang understands the significance of adapting pumps to align with client demands to ensure performance in diverse application settings. They provide a variety of OEM services that support the creation of pumps with measurements and materials well as components to offer a complete solution, for your requirements.

Moreover, Longgangs commitment, to customization enables adaptability in design and functionality options. This may involve incorporating monitoring systems tweaking pump casing setups or altering impeller designs to enhance efficiency. These personalized adjustments play a role in enhancing the efficiency of the pumps and reducing downtime during maintenance intervals. With an emphasis on customer solutions, Longgang emerges as a dependable ally, in developing systems that align perfectly with distinct operational objectives.

Furthermore, the customization procedure is backed by an engineering team, at Longgang that utilizes software and modeling methods to replicate pump performance in various operational scenarios This thorough examination is crucial for a guarantee that the tailored pumps meet industry benchmarks, like API610, and also cater to your unique operational requirements It showcases Longgangs dedication to innovation and outstanding service in the realm of single stage centrifugal pumps.

Longgang has established itself as a frontrunner, in the pump manufacturing sector by providing personalized solutions to cater to a range of customer requirements. With an emphasis, on design and customized services, Longgang ensures attention to all facets of single-stage centrifugal pump applications. Their collaborative strategy allows customers to access optimized pumping systems that boost efficiency in industries.