Having the pump perform optimally means productivity and cost savings while also ensuring it lasts longer. Looking at performance markers and using tools effectively can help you spot ways to do better and come up with plans to boost performance levels.

Key Performance Indicators

Flow Rate

The flow rate serves as a measure of how the pump is performing by measuring the amount of fluid passing through it within a specific period crucial, for meeting system requirements. When your API 610 pump operates at a flow rate than needed it may be essential to make changes to enhance its efficiency to a level.

Pressure Head

One important metric to consider is the pressure head measurement that gauges the energy transferred to the liquid by the pump system. It’s vital to keep an eye on the pressure head to guarantee that the pump delivers the pressure levels to the setup. A low-pressure head might signal challenges or a possible malfunction, in the pump system that requires examination.

Power Consumption

Monitoring power consumption metrics is crucial, for assessing your pump’s efficiency levels excessive energy usage might indicate the performance of your API 610 pump system. By keeping track of these indicators and spotting any inefficiencies on allows you to implement corrective actions to enhance energy efficiency and lower operational expenses effectively.

Diagnostic Tools and Methods

Using tools, like flow meters and pressure gauges along with power analyzers to analyze your API 610 pump performance status can help you gain insights, into its operation effectiveness. Vigilantly monitoring these tools enables you to promptly detect any performance-related concerns. Vibration analysis and infrared thermography techniques can also offer information on the pump’s condition.

Factors Affecting API 610 Pumps Optimal Performance

Some elements can impact the performance of your API 610 pump and being aware of these factors enables you to proactively manage and maintain it for consistent efficiency.

Installation Considerations

Proper installation is vital for the pump to function effectively and efficiently as intended by the manufacturer guidelines need to be followed during installation concerning the piping arrangement and elevation as well as valve positioning to ensure optimal performance of the pump errors in installation can lead to issues, like cavitation or insufficient suction which can affect its operation negatively.

Maintenance Requirements

Ensuring your pump operates smoothly requires maintenance efforts to avoid downtimes and inefficiencies, in its performance over time. Regularly servicing and inspecting your API 610 pump along, with replacing worn-out parts can significantly enhance its durability and operational efficiency.

Common Operational Challenges

It is important to be aware of the hurdles faced in operations to ensure smooth performance upkeep and efficiency of pumps might be affected by problems such, as blockages or seal deterioration and misalignment issues taking measures to tackle these obstacles can help in ensuring uninterrupted operations and keeping things running efficiently.

Using top-notch API 610 pumps, like the ones from Longgang can boost efficiency a deal! Longgang offers a selection of API 610 pumps tailored for industrial needs with a focus on durability and performance excellence, in various settings perfectly suited for different industries as well as providing exceptional customer support to ensure manufacturers receive expert guidance and reliable services throughout the pump’s lifespan. By embracing Longgangs cutting edge solutions you can set up your operations for lasting efficiency and effectiveness.

To maintain peak performance levels, your API 610 pump entails evaluation of its efficiency indicators. Ensuring meticulous installation and dedicated upkeep efforts are, in place. Focusing on these aspects not only boosts your pump’s performance but also leads to improved operational results overall.

Engaging in assessments will help you pinpoint areas, for enhancement and address any risks linked to performance challenges effectively and strategically. Take advantage of resources and techniques in collaboration with trusted vendors such, as Longgang to uphold the efficient operation of your API 610 pump system.

Take the initiative to evaluate the effectiveness of your API 610 pump performance to unlock its capabilities and protect your goals.

Longgang’s Contribution to API 610 Pumps

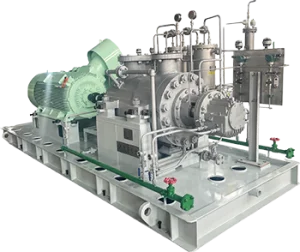

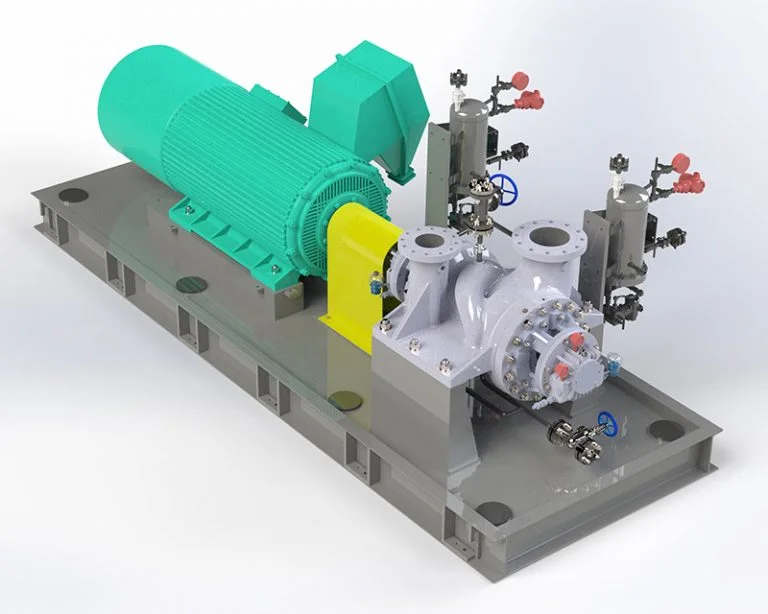

Longgang has become a provider of API 610 pumps that play a crucial role, in different industrial operations. The API 610 guidelines focus on the specifications and uses of pumps in sectors like petroleum and chemicals. This ensures handling with a strong emphasis on safety and efficiency. Longgangs dedication to excellence is showcased through its range of products tailored to meet the requirements set by API 610. This has solidified their reputation as an option, for engineers and manufacturers.

Longgang’s Product Range and Specifications

Longgang’s extensive product portfolio includes various models of API 610 pumps tailored to meet diverse industry needs. Each pump is meticulously designed with features that enhance fluid dynamics and operational efficiency. The construction materials used in Longgang pumps are selected specifically for their durability and resistance to corrosion, which is essential for maintaining optimal performance in challenging environments.

The specifications of Longgang’s API 610 pumps cater to different flow rates and pressure heads, accommodating a variety of applications including oil refining, petrochemical production, and water treatment. Moreover, Longgang ensures that all pumps are customizable to fit specific operational conditions. These offerings underscore the company’s flexibility and commitment to client satisfaction.

Beyond performance, Longgang also highlights the installation features of its pumps. Each product comes with comprehensive manuals that guide engineers through installation procedures, minimizing errors and ensuring that each pump operates at its full potential from day one.

Industry Certifications and Standards Met by Longgang

Longgang understands the value of regulatory compliance in building trust with customers. All their API 610 pumps meet or exceed industry certifications, ensuring that they adhere to safety and performance standards. Longgang’s dedication to quality control during manufacturing is reflected in their compliance with ISO and API standards, which signifies the durability and reliability of their products.

In addition, Longgang invests in continuous improvement and employee training, ensuring that its operational practices consistently align with the latest technological advances and regulatory requirements. This proactive approach to industry standards enables clients to operate in confidence, knowing that Longgang’s pumps are designed with both performance and safety in mind.

The company’s adherence to rigorous testing protocols guarantees that every API 610 pump performs consistently, even under the most demanding conditions. This dedication to excellence positions Longgang as a trusted partner in the oil, gas, and chemical industries, where performance and reliability are paramount.

Longgang’s API 610 pumps represent a fusion of innovation, performance, and industry compliance. By choosing Longgang, you are not only investing in advanced pump technology but also in a partnership that prioritizes your operational success. Collaborating with a supplier that understands the challenges of the industry will empower you to achieve the highest levels of efficiency and reliability in your applications.