When you’re choosing a pump to use for your needs and requirements, there are typically two types that are API pumps and non-API pumps. It’s important to consider this choice since each type of pump offers its set of advantages and disadvantages depending on the tasks you need it for. This article is dedicated to explaining the disparities between API pumps and non-API pumps to assist you in making a decision about which option is the most suitable for you.

Understanding the Choice Between API and Non-API Pumps

It’s crucial to grasp the differences between these types of pumps before coming to a decision.

API Pumps: Engineered for Demanding Applications

Pumps created for API compliance adhere to the guidelines set by the American Petroleum Institute (API). These guidelines ensure top-notch engineering precision and the use of premium materials along with testing processes that lead to pumps renowned for their dependability and resilience in demanding conditions.

Precision and Reliability

In industries like oil and gas and petrochemicals and refining sectors API pumps are popular for managing fluids at pressures and temperatures. They are designed to withstand conditions ensuring performance over time with little need for maintenance.

Rigorous Testing

Pumps in the API are subjected to evaluations such as performance assessments and mechanical trials to meet industry regulations and standards effectively for operators’ peace of mind by reducing the chances of operational disruptions or mechanical breakdowns.

Non-API Pumps: Versatility and Cost-Effectiveness

Pumps that do not adhere to API standards offer flexibility and affordability across a range of uses due to their adaptability and customization options that cater to needs in different industries and fluid handling scenarios.

Versatility and Adaptability

Non-API pumps offer an advantage due to their flexibility in design and configuration options to manufacturers. They can be customized to suit application requirements such as managing fluid types or meeting specific flow rates and environmental conditions. This adaptability makes them ideal for sectors like water treatment, such as those industries in the food and beverage sector and pharmaceutical companies.

Cost-Effectiveness

Non-API pumps usually come with a price tag compared to API pumps and are often preferred for projects with budget limitations or situations where top-notch accuracy and dependability are not absolute necessities. Nevertheless, it’s important to take into account the prolonged expenses and maintenance needs while assessing the cost-effectiveness of non-API pumps.

Factors to Consider When Choosing Between API and Non-API Pumps

Choosing the pump for your use requires a thorough assessment of a range of different considerations.

Operating Conditions

- Carefully analyze the fluid properties, temperature, pressure, and environmental conditions in which the pump will function.

- API pumps excel in high-pressure and high-temperature environments, while non-API pumps offer greater versatility for a wider range of operating conditions.

Reliability Requirements

- Consider the application’s criticality and the potential repercussions of pump failure.

- API pumps are renowned for their reliability and undergo stringent testing to guarantee performance in demanding conditions, making them well-suited for mission-critical applications.

Budget Constraints

- Evaluate both the initial investment cost and the long-term operating and maintenance expenses.

- While non-API pumps may offer a more cost-effective solution upfront, API pumps often deliver superior reliability and performance throughout the equipment’s lifespan.

Customization Needs

- Determine if your application demands any specific customizations to the pump.

- Non-API pumps provide greater flexibility in design and configuration, enabling tailored solutions for unique challenges.

Industries Where Non-API Pumps May Be Preferred

Non-API pumps are commonly favored in industries where strict regulations and higher expenses linked to API pumps might not be required.

Industries with Less Stringent Requirements

Certain sectors have demands when it comes to pumping performance and dependability requirements are not as stringent in these instances where non-API pumps can provide a budget-friendly option for solutions needed by industries like;

- General Manufacturing

- Agriculture

- Light industrial applications

Applications with Less Demanding Operating Conditions

In fields of work or sectors of industry, there are situations where the functionalities of API pumps that operate under pressure and temperature conditions may not be necessary. Non-API pumps could serve as an alternative in these cases. Some instances where non-API pumps could be suitable include;

- Water transfer in municipal water systems

- Irrigation systems

- HVAC systems

Yantai Longgang Pump Industry: A Reliable Non-API Pump Supplier

Yantai Longgang Pump Industry is well known for producing API pumps and providing a variety of products to meet the specific requirements of different industries.

Manufacturing Expertise and Industry Recognition

Established in 2001, Yantai Longgang Pump Industry has garnered accolades such as being labeled a “high-tech enterprise ” and a “Contract abiding and enterprise “. A “Shandong Province specialized and innovative enterprise.” The company’s achievements include winning the China Machinery Industry Science and Technology Progress First Prize “as well as the esteemed “Zhejiang Province Science and Technology Progress Award.” Yantai Longgang also serves as an approved supplier for companies like CNPC, Sinopec, and CNOOC demonstrating its proficiency and dependability in the pump industry.

Diverse Product Line Catering to Various Needs

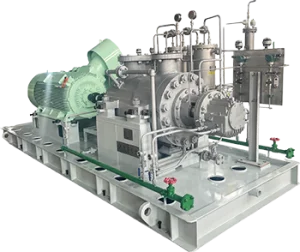

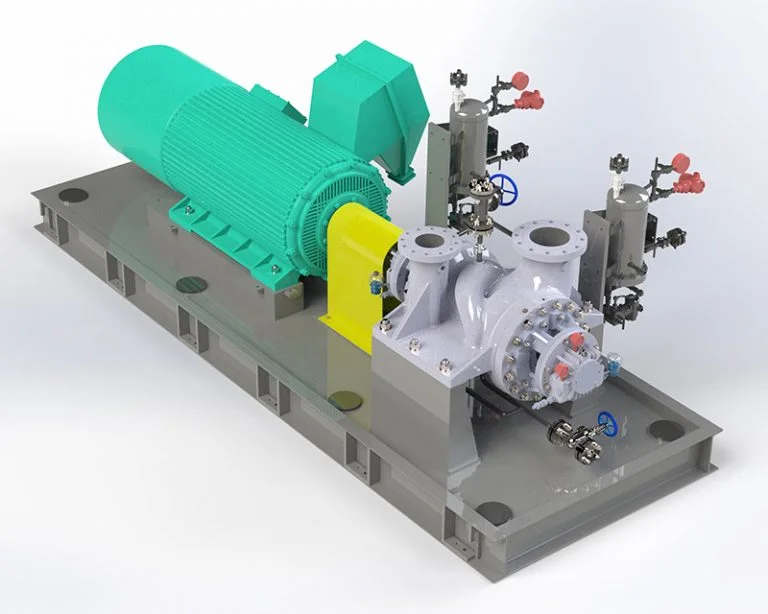

At Yantai Longgangs facility they focus primarily on manufacturing a range of API pumps such as the BB series pumps and OH series pumps along with the VS series chemical centrifugal pumps to cater to different industries’ requirements including;

- Petroleum and Petrochemical:Providing solutions for oil refining and ethylene production.

- Coal Chemical Industry:Supplying pumps for coal gasification, liquefaction, and other processes.

- Environmental Protection and Water Treatment:Offering pumps for water treatment applications.

Commitment to Quality and Customer Service

At Yantai Longgang Corporation core is a focus on delivering top-notch products and excellent customer service standards certified by ISO9001 2008 and the American Petroleum Institute API quality system certification badges proudly displayed in their accolades list. They hold the title of Grade A supplier to China National Petroleum Corporation and are approved vendors for Sinopec CNOOC China Chemical Group and China National Salt Industry Corporation. Their dedication to quality assurance and customer happiness shines through their unwavering commitment to delivering top-notch services;

- Quality assurance:A 12/18 month warranty on all products and lifetime service.

- Professional team:Technical and after-sales service personnel are available for installation and testing assistance.

- Timely service:Providing qualified spare parts as needed.

- Regular return visits:Collecting feedback on product quality.

- 24-hour problem resolution:Ensuring prompt responses and solutions to any quality issues.

Conclusion

When deciding between API and non API pumps, it all comes down to what your application requires. API pumps are preferred for situations with pressure and high temperatures such as in industries like oil and gas. Non API pumps on the other hand give you flexibility and cost savings making them a good fit for a range of applications in different fields.

When you thoroughly assess your environment and consider factors like reliability standards and budget constraints alongside your customization preferences, you can confidently choose the best approach to enhance the efficiency of your fluid management operations. Organizations such as Yantai Longgang Pump Industry provide a selection of non-API pumps that showcase their dedication to catering to the varied requirements of clients spanning various sectors.