Canned motor pumps are gaining traction in various industries due to their superior efficiencies and innovative design modifications. As we witness growing environmental concerns and energy efficiency requirements, this article explores emerging trends in canned motor pump technology. By understanding recent innovations, stakeholders can strategically position themselves to maximize performance and reliability.

Overview of the Canned Motor Pumps Market

The canned motor pumps market has been expanding steadily as industries seek more reliable and efficient pumping solutions. The growth of the market is attributed to the continuous need for high-performance fluid handling in diverse applications. Additionally, reputable companies are increasingly focusing on the development of advanced pump technologies to meet the rigorous standards set by regulatory bodies.

Key Drivers of Demand

Several factors drive demand for canned motor pumps. A significant contributor is the consistent need for robust solutions in hazardous environments. Industries are leaning towards innovative designs that adhere to safety and operational regulations. Furthermore, the need for reduced maintenance downtimes is pushing enterprises to invest in advanced canned motor pumps, which require lower operational efforts and maintenance compared to traditional pumps.

Increased Efficiency and Performance

Recent advancements have significantly enhanced the efficiency and performance capacities of canned motor pumps. These enhancements have made these pumps popular choices in various demanding applications. The focus on energy consumption and thermal management has become paramount as industries strive for improved operational effectiveness.

Enhancements in Motor Design

Innovative motor design enhancements have led to substantial efficiency gains. Modern canned motor pumps feature designs that minimize energy losses while maximizing fluid dynamics, resulting in more efficient operation across diverse applications.

Reduced Energy Consumption

Technology is now focused on motor designs that utilize less energy while maintaining performance. By integrating advanced magnetic materials and optimized winding configurations, the energy consumption of canned motor pumps is reduced significantly during operation, thus lowering operational costs.

Improved Thermal Management

Enhanced thermal management systems have been incorporated into the latest canned motor pump designs. These systems efficiently dissipate heat generated during operation, enabling the pumps to maintain optimal performance even in high-demand scenarios and extreme temperatures.

Upgraded Hydraulics for Better Fluid Handling

The hydraulic systems used in canned motor pumps have seen noteworthy upgrades, enhancing their fluid handling capabilities. Key advancements revolve around impeller design and bearing systems, contributing to better operational efficiencies.

High-Performance Impellers

The latest canned motor pumps are equipped with high-performance impellers designed for minimal cavitation and maximum flow efficiency. These advancements help in optimizing fluid handling, enabling even the most challenging applications to be carried out smoothly.

Advanced Bearing Systems

The introduction of advanced bearing systems has significantly improved the reliability and lifespan of canned motor pumps. These bearings not only provide enhanced stability but also reduce friction, leading to lower wear and tear. As a result, the overall performance and efficiency of the pump are notably elevated.

Expansion of Application Areas

The application areas of canned motor pumps have expanded significantly, owing to technological advancements that cater to various environmental conditions. Industries benefit from these pumps as they adapt to various demanding environments.

Adaptations for Extreme Environments

Canned motor pumps have increasingly been adapted for extreme conditions. This has opened new market segments and applications, enhancing the versatility of these pumps.

Submersible Applications

The ability of canned motor pumps to function reliably in submersible applications has made them key players in wastewater management and other underground processes. The integration of specialized seals and materials allows for effective pumping even when submerged.

High-Temperature Operations

High-temperature operations present unique challenges, and canned motor pumps have evolved to tackle these challenges effectively. New materials and designs are being implemented to ensure the pumps can handle high-temperature fluids without compromising performance or lifespan.

Integration with Renewable Energy Systems

There is a growing trend towards integrating canned motor pumps with renewable energy systems. This convergence is particularly visible in applications such as solar thermal systems and biogas installations, where efficient fluid transport is paramount.

Smart and Connected Technologies

The emergence of smart and connected technologies in canned motor pumps signifies a transformative shift in pump operations. IoT integration plays a central role in enhancing performance, predictive capabilities, and overall system management.

IoT Integration for Real-Time Monitoring

Companies are increasingly adopting IoT technologies to enable real-time monitoring of canned motor pumps, thereby enhancing the reliability of operations. Real-time data analytics allows operators to identify issues before they lead to downtime, optimizing maintenance and performance.

Predictive Maintenance Capabilities

Predictive maintenance is revolutionizing how industries manage their canned motor pumps. By utilizing data analytics, businesses can predict potential failures and address them proactively, significantly reducing unexpected downtimes.

Remote Diagnostics and Control

Remote diagnostics and control technologies provide operators with the ability to monitor and adjust operations from anywhere. This not only enhances efficiency but also boosts safety, as personnel can make informed decisions based on real-time data without needing to be onsite.

Advanced Sensors and Data Analytics

The advancement of sensor technology has enabled better data collection, thereby improving the operation of canned motor pumps. Enhanced data analytics can lead to smarter decision-making, ensuring pumps operate at their optimal efficiency while minimizing the environmental impact.

In conclusion, the canned motor pump market is evolving rapidly, driven by a variety of factors including technological advancements, the demand for increased efficiency, and the integration of smart technologies. Adopting these emerging trends will be crucial for businesses aiming to enhance their fluid handling operations and maintain competitiveness in an increasingly regulated and energy-conscious world.

Compliance with Environmental Regulations

In response to heightened environmental awareness, the canned motor pump industry is increasingly emphasizing compliance with regulations. Adopting eco-friendly practices is essential to meet global standards and consumer expectations, leading to advancements that support sustainability.

Development of Eco-Friendly Pumps

The development of eco-friendly canned motor pumps is becoming more prevalent, reflecting the industry’s commitment to sustainability. By focusing on designs that minimize environmental impacts, manufacturers are investing in innovative solutions that resonate with today’s environmental consciousness.

Use of Recyclable Materials

One prominent trend is the utilization of recyclable materials in the construction of canned motor pumps. Manufacturers are now integrating materials such as stainless steel and composites, which, upon reaching the end of their service life, can be recycled efficiently. This not only reduces waste but also conserves natural resources, making it a win-win scenario for the environment and the industry.

Low Emission Designs

Another significant advancement associated with eco-friendly pumps is the move towards low emission designs. These pumps are engineered to reduce the escape of harmful pollutants during operation, thereby significantly minimizing their ecological footprint. Companies are also focusing on optimizing engine performance, enabling engines to operate more cleanly and efficiently, thereby adhering to stricter environmental regulations while maintaining high operational standards.

Adherence to Global Standards

Compliance with global standards is non-negotiable in the canned motor pump domain. Manufacturers are dedicating resources to understand and integrate international standards into their design and manufacturing processes. This adherence fosters trust and credibility in the market while ensuring that products are safe and reliable.

Focus on Cost-Effectiveness and Profitability

As industries strive to optimize expenditures, the focus on cost-effective solutions is paramount in the canned motor pump sector. Manufacturers are innovating processes and technologies, thereby enhancing the profitability of these pumps for businesses involved.

Manufacturing Innovations to Reduce Costs

Innovation in manufacturing processes not only improves efficiency but also drives down costs associated with canned motor pump production. By pioneering new techniques and utilizing state-of-the-art equipment, manufacturers can streamline operations and reduce overhead.

Robotics and Automation in Production

The integration of robotics and automation into production lines has transformed the manufacturing landscape for canned motor pumps. Automation ensures precision and consistency, which is crucial in creating reliable products. Furthermore, it significantly reduces labor costs and errors while allowing for increased production rates to meet market demands. Companies leveraging these technologies find themselves well-positioned athwart procurement and scalability challenges.

Economies of Scale

Additionally, serial production advancements have generated economies of scale that benefit manufacturers and end-users alike. The increased output allows firms to spread costs over a larger production volume, translating into more competitive pricing structures for consumers. Strategic partnerships and shared resources also promote collaborative efficiencies, ensuring that the market remains robust and affordable.

Enhanced Durability for Long-Term Savings

An essential aspect of focusing on cost-effectiveness is enhancing the durability of canned motor pumps. The longer the equipment lasts, the less frequently businesses need to invest in replacements or repairs.

How Longgang Pumps is Pioneering the Future of Canned Motor Pumps

A key player in this market is longgang Pumps, known for its commitment to innovation and quality. The company has introduced several models that showcase advanced technology and design principles, shaping the future of canned motor pumps.

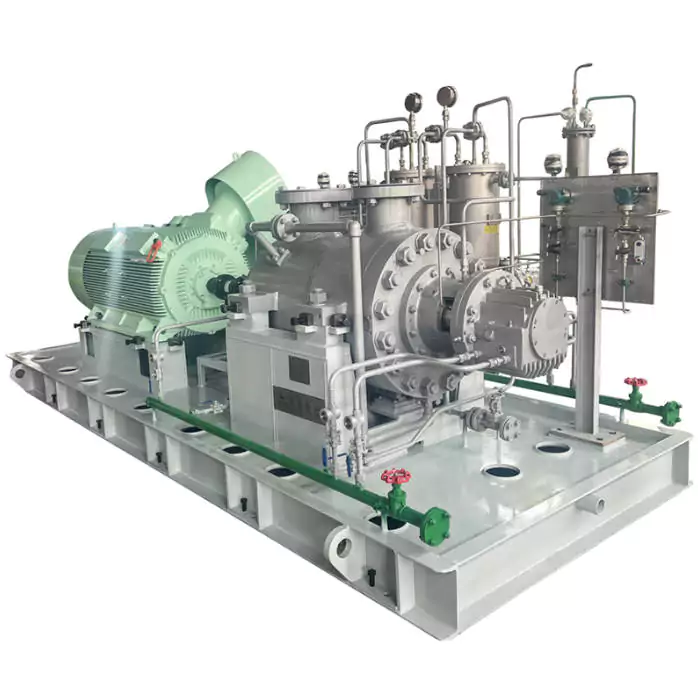

BB1-AXIALLY SPLIT DOUBLE SUCTION CENTRIFUGAL PUMP

This series is a single-stage or two-stage, double-suction,between-bearing pump, designed according to the APl610 1 1th edition andAPl682 3rd edition ”Centrifugal Pumps and Rotary Pumps Shaft Sealing Systems” standards.

It is mainly used to transport clean or liquid containing trace particles, such as petrochemical industry, hydro-irrigation, industrial power plants, industrial desalination projects (reverse osmosis method) and combined cycle power plants, solar energy utilization, biochemistry and other fields.

As canned motor pump technology continues to evolve, it is evident that compliance with environmental regulations and a focus on profitability will drive innovation. With manufacturers like longgang Pumps leading the charge, the future of canned motor pumps holds great potential, combining efficiency, sustainability, and reliability to meet the diverse needs of industries worldwide.