Introduction to Centrifugal Pumps

As the most common fluid-conveying equipment in industrial and civil fields, centrifugal pumps achieve liquid transportation through the centrifugal force generated by a rotating impeller. There are a wide variety of centrifugal pumps, which can be classified according to their structure, function, and application.

Main Types of Centrifugal Pumps

Classified by Impeller Design & Stages

- Single-Stage VS. Multi-stage Centrifugal Pumps

Single-stage centrifugal pump: It contains only one impeller, with a simple structure and convenient maintenance.

Application: It is suitable for low-head scenarios, such as building water supply and agricultural irrigation.

Multi-stage centrifugal pump: Multiple impellers are connected in series, increasing the pressure stage by stage, and the head can reach hundreds of meters.

Application: It is mostly used for high-pressure requirements, such as mine drainage and boiler feed water.

- Open VS. Closed Impeller Pumps

Closed impeller: There are covers on both sides of the blades. It has high efficiency and is suitable for clean liquids (such as clean water and oils).

Open impeller: Without covers, it has strong anti-clogging ability and is suitable for liquids containing impurities (such as sewage and slurry).

Semi-open impeller: It has a single-side cover, featuring both efficiency and anti-clogging ability. It is commonly seen in the chemical industry.

By Shaft Orientation & Installation

- Horizontal VS. Vertical Centrifugal Pumps

Horizontal centrifugal pump: With its pump shaft placed horizontally, it is easy to install and maintain, and is widely applied in factories and municipal engineering.

Vertical centrifugal pump: The pump shaft is designed vertically, occupying a small floor area. It is suitable for scenarios with limited space, such as on ships and for deep-well water intake.

- Pipeline Pump VS. Submersible Pump

Pipeline Pump: It is directly embedded in the pipeline system and doesn’t require a foundation. It is used for pressure-boosting transportation (such as in HVAC systems and industrial circulation systems).

Submersible Pump: The motor and the pump body are integrated, and it works completely submerged in the liquid. It is specifically used for draining deep wells and ponds.

By Suction & Sealing Technology

- Single-suction VS. Double-suction Centrifugal Pump

Single-suction Centrifugal Pump: Liquid is sucked in from one side of the impeller. It has a simple structure, but there is an axial force, so a thrust bearing needs to be equipped.

Double-suction Centrifugal Pump: Liquid is sucked in from both sides. It has a large flow rate and the axial force is self-balanced. It is suitable for large-flow-rate scenarios (such as in water treatment plants and water conservancy projects).

- Magnetic-drive Pump VS. Self-priming Pump

Magnetic-drive Pump: It has no mechanical seal and transfers power through magnetic coupling, completely eliminating leakage. It is used for transporting toxic and flammable media (in the chemical and pharmaceutical industries).

Self-priming Pump: It doesn’t need to be filled with water before startup and can automatically exhaust air. It is suitable for working conditions with frequent starts and stops or when the liquid level is lower than the pump (such as in farmland drainage and irrigation and vehicle washing).

By Media & Industry Applications

Clean-water Centrifugal Pump: It is used to transport pure water or low-viscosity liquids. The materials are mostly cast iron or stainless steel (used in domestic water supply and cooling systems).

Corrosion-resistant Centrifugal Pump: It is made of materials such as stainless steel and fluoroplastic, and can resist acid and alkali media (used in the chemical and electroplating industries).

Impurity-handling Centrifugal Pump: It is equipped with a wear-resistant impeller and a wide flow channel and is used for liquids containing particles and fibers (such as in mine slag removal and sewage treatment).

High-temperature Centrifugal Pump: It has a special sealing and cooling design and can transport high-temperature media (in thermal power stations and oil refining).

Specialized Centrifugal Pumps

Fire-fighting Pump: It is designed with a high head and a large flow rate to meet emergency fire-fighting needs (used in fire-fighting systems and emergency drainage).

Variable-frequency Centrifugal Pump: It integrates a variable-frequency speed-regulating function, can adjust the flow rate as needed, and has a significant energy-saving effect (used in building water supply and industrial circulation).

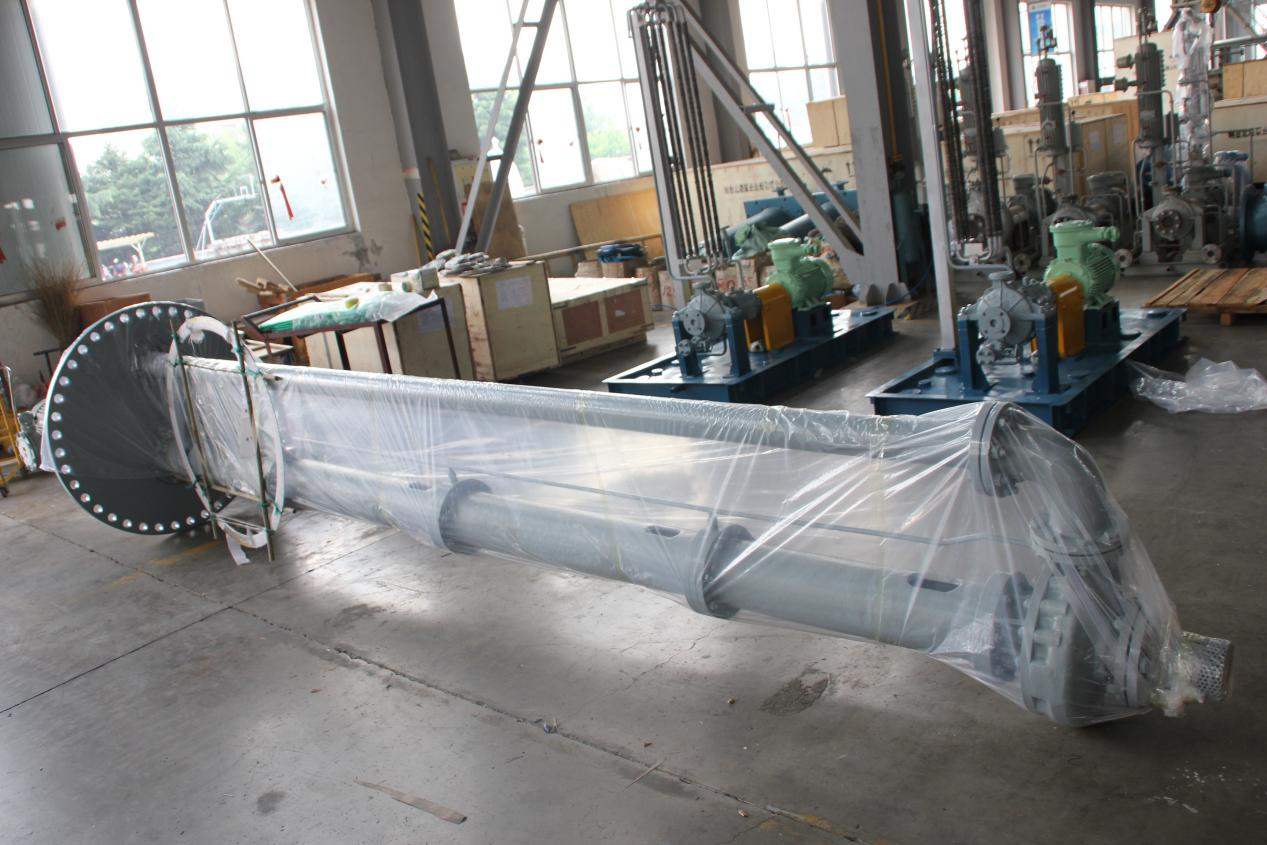

Deep-well Submersible Pump: It has a long-shaft design and is specifically used for extracting water from deep wells hundreds of meters underground (used in agricultural irrigation and rural drinking water projects).

How to Select the Right Centrifugal Pump

When selecting a centrifugal pump, factors such as the characteristics of the medium (viscosity, corrosiveness, impurity content), the requirements of the working conditions (flow rate, head, temperature), and the environmental conditions (installation space, power supply configuration) need to be comprehensively considered. For example, when transporting sewage, a horizontal impurity pump with an open impeller should be selected, while for transporting corrosive chemical liquids, a fluoroplastic magnetic-drive pump is required. By accurately matching the type with the scenario, the efficiency and service life of the equipment can be significantly improved.

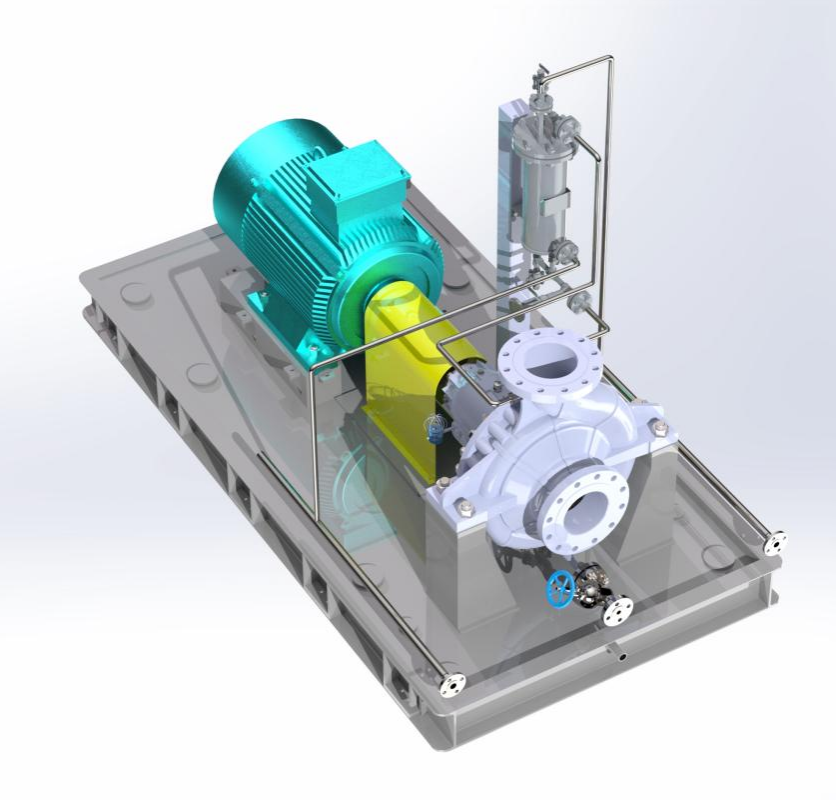

Longgang Pump Industry’s Centrifugal Pump Products

As a professional centrifugal pump manufacturing enterprise, Longgang Pump Industry has been deeply engaged in the field of petrochemical pumps for 22 years, mainly producing high-end, high-efficiency, and heavy-duty chemical centrifugal pumps. The total area of our production workshop is 10,000 square meters. It is equipped with an efficient machine-electricity-instrument integrated supporting platform, and a standardized assembly line operation is carried out using a standard management mode that complies with the API Q1 system. We have the production capacity of 500 sets of BB/VS high-end pumps and 3,000 sets of OH-series pumps per year.

For more details, please click here to view our product catalog.

Should you have any queries regarding the selection of centrifugal pumps, feel free to reach out to our technical team. We’re more than ready to offer you a tailor-made solution, meticulously crafted to meet your specific requirements.