Selecting the right pump for your industrial applications involves considering the differences between API 610 pumps and non-API pumps. Explore the reliability, durability, efficiency, and cost considerations of API 610 pumps compared to non-API pumps. Discover Longgang’s comprehensive range of API 610 compliant pumps and non-API pump solutions, designed to meet diverse industrial needs. Choose the pump solution that aligns with your specific operational requirements for optimal performance and cost-effectiveness.

Understanding API 610 Pump Standards

API 610 is an acknowledged guideline that sets out the criteria, for centrifugal pumps utilized in the petroleum industry as well as in petrochemical and natural gas sectors to guarantee their durability under challenging operating conditions and consistent performance delivery.

Historical Background of API 610

The API 610 standard was created by the American Petroleum Institute to ensure that pump design and production are consistent and reliable, in meeting industry requirements over time by adapting to progress and feedback, from the field.

Technical Specifications of API 610 Pumps

Pumps compliant, with API 610 guidelines are meticulously crafted to endure temperatures and manage liquids effectively using sturdy materials and precise engineering techniques in their construction process. These pumps typically come with casings that split radially and are designed for maintenance and extended durability, through pull-out configurations.

Applications and Industries Utilizing API 610 Pumps

API 610 pumps are mainly utilized in sectors that prioritize safety and dependability. Like oil refineries, chemical plants, and offshore drilling sites. They play a role, in managing hydrocarbons and other dangerous liquids at pressures.

Characteristics of Non-API Pumps

Non-API pumps may not comply with the guidelines established by the American Petroleum Institute. They are utilized in a variety of applications, across different industries.

General Features of Non-API Pumps

Non-API pumps come in designs and applications that can be customized for needs by using different materials and configurations depending on the type of fluid being handled as well as the temperature and pressure requirements involved in the process. Times these pumps focus more on creating cost solutions rather, than standard features typically found in other pumps.

Common Applications for Non-API Pumps

Non-API pumps are often utilized in scenarios where their API equivalents are used for their application, in water treatment plants, and in general industrial processes where extreme conditions do not play a significant role.

Ultimately when it comes to selecting between API 610 pump variants and non API pumps for purposes it all boils down to the demands of your operation. If you seek top-notch pump options customized to suit your requirements I recommend checking out the selection of products, at Longgang.

Comparing Performance: API 610 vs. Non-API Pumps

When evaluating API 610 pump varieties, versus API pumps one must take into account various performance factors that could affect operational efficiency and expenses.

Reliability and Durability Aspects

API 610 pumps are well known for their reputation of being lasting machines built to withstand tough conditions, in industries such as petrochemical and natural gas sectors. They are constructed using materials and adhere to manufacturing standards to guarantee a longer lifespan making them a preferred option for critical operations where interruptions cannot be tolerated. On the other hand, pumps that do not meet API standards may lack the level of durability but could be a budget-friendly choice, for less rigorous settings.

Efficiency and Operational Costs

Choosing the pump involves considering efficiency as a factor to keep in mind during the selection process. API 610 pumps are specifically designed to be highly efficient which helps in saving energy and cutting down expenses in the run. These pumps usually come with features that enhance flow optimization and reduce losses. The other e han,non-on API pumps may seem cheaper initially. This could lead to higher operational costs due, to their less efficient designs. Hence it is important to balance the long-term savings, against the initial investment when deciding between these two types of pumps.

Selecting the Right Pump for Your Needs

Selecting the pump requires considering aspects beyond solely focusing on performance specifications.

Factors to Consider When Choosing Between API 610 and Non-API Pumps

When choosing between API 610 pumps and non-API pumps for your pumping needs take into account the characteristics of the liquid being pumped the pressure levels needed the temperature conditions and how crucial the application is. In situations where safety and dependability are priorities API 610 pumps are usually the go-to choice. If your requirements are not as strict or if you’re working within budget constraints API pumps could be a better fit.

Longgang’s Product Offerings in Pump Technology

Longgang offers a comprehensive range of pump solutions catering to both API 610 standards and non-API applications. Their products are designed with precision engineering to meet diverse industrial needs.

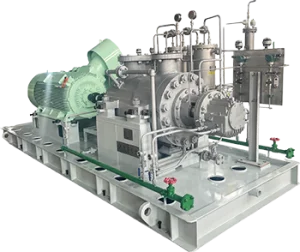

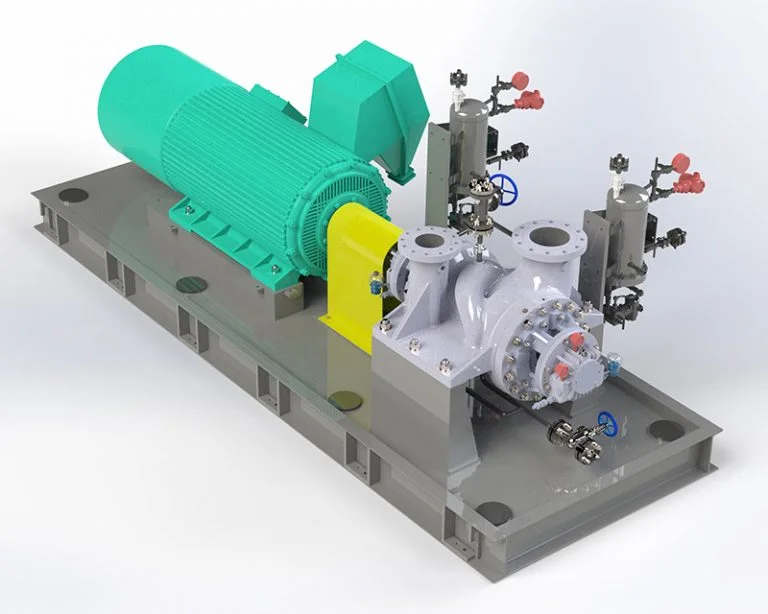

Overview of Longgang’s API 610 Compliant Pumps

Longgang’s line of API 610-compliant pumps is crafted with high-grade materials ensuring exceptional performance under extreme conditions. These pumps are ideal for industries requiring adherence to strict safety standards. To explore Longgang’s offerings in this category, you can visit their website.

Range of Non-API Pump Solutions by Longgang

For applications where flexibility and cost-effectiveness are priorities, Longgang provides a variety of non-API pump solutions. These products offer customizable features tailored to specific operational needs without compromising on quality. Discover more about their non-API options by visiting their website.

In summary, understanding your specific industrial requirements is crucial in selecting between API 610 pump types and non-API pumps. Each has its advantages depending on your operational context, budget considerations, and performance expectations. By considering these factors carefully, you can ensure optimal efficiency and reliability in your pumping systems.