Chemical pumps are essential, for moving fluids in various industries thanks to their advanced engineering and sturdy design features that ensure reliability and compliance, with regulations. Yantai Longgang Pump Industry Co. Ltd is a known supplier known for its selection of chemical pumps tailored to handle different fluid needs efficiently. These pumps are specially designed for tasks involving temperatures and corrosive materials to demonstrate their expertise in transporting difficult substances effectively.

Definition and Primary Functions of Chemical Pumps

Pumps used for handling corrosive fluids are specially crafted to ensure operation by effectively managing these substance’s transport and pressure in industries such, as petrochemicals and pharmaceuticals, among others.

How Chemical Pumps Work

Chemical pumps work, by transforming energy into energy to push fluid through pipes using either centrifugal force or positive displacement methods. Centrifugal pumps utilize spinning impellers to create flow while positive displacement pumps move a volume of fluid in each cycle. Regardless of the type used chemical pumps are carefully crafted to manage requirements, for durability and dependability.

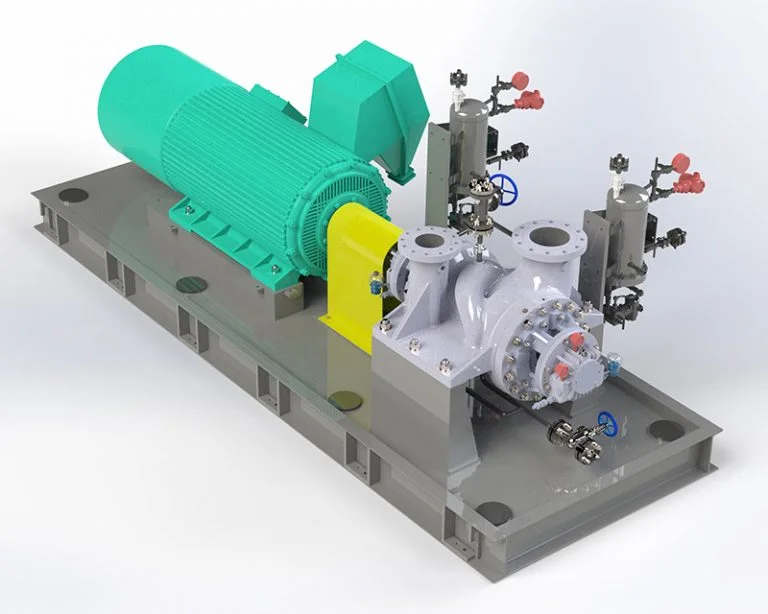

Components and Materials Used in Chemical Pumps

Chemical pump designs focus heavily on using materials that can handle conditions. Key components, like impellers, seals, and casings play a role in how they work. Yantai Longgang produces pumps using high-quality materials such as duplex steel for handling chemicals ensuring their products are durable and dependable. Their innovative designs feature submerged sliding bearings and rolling bearings, for lubrication and operational efficiency.

Importance of Safe Fluid Handling

Handling fluids, in chemical processes can present dangers when not managed correctly. Understanding the significance of management is crucial for keeping operations efficient and reducing risks. Chemical pumps play a role, in managing these dangers by protecting people and maintaining equipment integrity.

Risks Associated with Improper Fluid Handling

Mishandling chemicals may cause leaks or spills which can lead to damage and injuries while also resulting in costs, for repairs and cleanup efforts. Equipment malfunctions do not endanger the safety of individuals. Can also interrupt manufacturing operations. Recognizing these hazards highlights the importance of using machinery such as chemical pumps, to securely transport fluids.

Industry Standards and Regulations

Meeting industry standards and regulations is crucial, for maintaining chemical handling practices in the workplace for manufacturers and operators. Longgang’s pumps are designed with engineering. Undergo rigorous testing to meet ISO9001 certification and other relevant industry standards. This ensures that the pumps are dependable and safe for use, in demanding applications.

Industries can enhance their handling operations. Adhere, to safety regulations, by opting for Longgangs chemical pumps while also striving for operational excellence.

Longgang’s Advanced Chemical Pumps Solutions

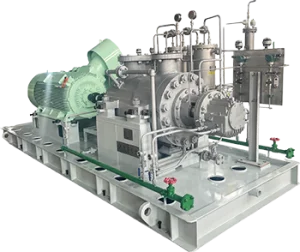

Overview of Longgang’s Product Line

The Yantai Longgang Pump Industry Company has positioned itself as a player, in the realm of chemical pumps by offering a range of cutting-edge solutions designed for demanding fluid management tasks that prioritize efficiency and dependability in challenging conditions. Their chemical pumps are intricately engineered to deliver top-notch performance and durability under the circumstances. Showcasing a dedication, to advancements and product excellence the company partners with universities and research organizations to consistently improve their offerings and remain at the forefront of industry developments.

Longgang doesn’t just offer chemical pumps – they are experts, in creating pump solutions to meet the unique requirements of clients in different industries. One example of their expertise is seen in how their pumps move fluids that are low in temperature and prone to vaporization and corrosion – a demonstration of their adaptability and effectiveness across various environments. Moreover! Longgang prioritizes the production of chemical pumps using alloy materials that can withstand chemicals effectively, for long-lasting durability and high performance.

Key Features and Benefits of Longgang’s Chemical Pumps

Longgang chemical pumps are equipped with a variety of characteristics that work together to improve their effectiveness and dependability.

Corrosion Resistance

Ensuring that chemical pumps have resistance, to corrosion is vital because numerous fluids can be harsh or corrosive. Longgang uses high-quality materials like duplex steel to make its pumps sturdy enough to endure conditions without sacrificing reliability. This feature helps reduce the need for maintenance and lowers the chances of shutdowns thus improving overall operational effectiveness. By opting for pumps, with corrosion resistance industries can confidently manage a range of chemicals without worrying about harming the equipment.

High Performance and Durability

Longgangs chemical pumps are designed to deliver top-notch performance and reliable outcomes consistently. These pumps boast stage configurations that enhance flow rates and pressure efficiency, and cutting-edge hydraulic design software, like PUMPCAD, ensures that each pump is fine-tuned for performance and dependability. With these design features Longgangs pumps exhibit durability effectively handling the demands of diverse fluid handling tasks while reducing overall costs over time.

Energy Efficiency

Longgang places an emphasis, on enhancing the energy efficiency of their chemical pumps for operational expenses and supports sustainability initiatives effectively by designing pumps that use minimal energy without compromising performance quality. This commitment to energy efficiency does not contribute positively to the environment. Also offers substantial cost savings for businesses. Choosing Longgangs eco products can lead to long-term energy savings and align, with broader sustainability objectives.

Applications of Chemical Pumps in Various Industries

Chemical pumps from Longgang find extensive applications across numerous industries due to their versatile design and performance characteristics.

Role in the Chemical Industry

In the chemical industry, reliable fluid handling is essential due to the hazardous nature of many substances involved. Longgang’s chemical pumps provide the necessary safety and efficiency to transport aggressive fluids, reducing the risk of leaks or spills. Their pumps are used for various applications, including the transfer of acids, bases, and solvents, ensuring compliance with industry regulations. By investing in high-quality chemical pumps from Longgang, companies can enhance their operational safety while ensuring reliable performance.

Usage in the Pharmaceutical Sector

The pharmaceutical sector demands precise and reliable equipment for the transport of sensitive materials. Longgang’s chemical pumps are designed to cater to these stringent requirements, ensuring that drugs are handled safely and efficiently throughout the manufacturing process. These pumps are engineered with features to minimize contamination risk, thereby maintaining product integrity. Furthermore, their ability to manage various flow rates and pressures enables pharmaceutical manufacturers to optimize production levels effectively.

Application in Water Treatment Facilities

Water treatment facilities rely heavily on chemical pumps to manage the varying processes involved in purifying water. Longgang’s pumps facilitate the injection of chemicals necessary for disinfection and treatment, ensuring water meets safety standards before supply. With a robust design tailored specifically for handling water treatment needs, Longgang’s chemical pumps significantly contribute to achieving clean water objectives. The reliability and efficiency of these pumps allow water treatment facilities to operate smoothly while maintaining environmental compliance.

In summary, chemical pumps are vital for safe fluid handling across multiple sectors. By integrating Longgang’s advanced chemical pump solutions, industries can enhance their operational capabilities while ensuring the efficient and safe transportation of various fluids. These pumps stand as a beacon of quality, performance, and safety, perfectly aligning with the diverse needs of modern industries.