Understanding Vertical Centrifugal Pumps

Definition and Basic Principles

Vertical centrifugal pumps are a pump variety crafted to transport liquids by transforming kinetic energy into hydrodynamic energy efficiently and effectively! Their vertical setup makes them space-saving champions, in applications with room to spare. The impeller pulls liquid from below. Energizes it with movement that eventually turns into pressure upon release, through the outlet. This operational approach is effective and applicable, across a range of uses—ranging from procedures to water provision.

How they Differ from Horizontal Pumps

Vertical and horizontal centrifugal pumps have characteristics when it comes to their orientation and installation needs. Vertical pumps are designed to stand upright and take up space compared to pumps which require a larger horizontal area, for installation. Horizontal pumps may also involve a bit of complexity during setup. On the other hand, self-priming vertical pumps are a fit, for situations where fluid levels fluctuate.

Advantages of Vertical Centrifugal Pumps

Space-Saving Design

Ideal for Compact Installations

The tall shape of these pumps offers advantages when it comes to saving space in cities where land is limited and, in high demand. They are thin enough to fit into areas without sacrificing their effectiveness. This compact design enables versatility in how they can be placed and installed which is a benefit, in busy industrial facilities.

Suitability for Urban Industrial Settings like Longgang

In places, like Longgang with setups having efficient solutions for managing fluids is crucial. Vertical centrifugal pumps prove to be highly useful in scenarios as they can be easily incorporated into the existing infrastructure without the need, for renovations. Longgang provides a range of centrifugal pumps designed to meet the specific needs of urban settings facilitating the movement of different fluids while also saving precious operational space.

Energy Efficiency

Lower Power Consumption Rates

Vertical centrifugal pumps come with designs that improve the flow of fluids and reduce energy usage compared to horizontal pumps They are made even more efficient, with the use of modern pump technology like variable frequency drives (VFDs) which help regulate pump speeds and energy usage effectively This results in reduced operational expenses and makes vertical centrifugal pumps a cost-effective choice, for various industries.

Economic Benefits Over Time

The upfront cost of pumps is usually offset by significant savings, in electricity and upkeep expenses throughout the pump’s lifetime. Therefore reliable performance and energy-efficient operation can lead to a return on investment for businesses while also contributing to the environment. Longgang‘s dedication, to innovation guarantees that their vertical centrifugal pumps incorporate state-of-the-art technologies that encourage energy conservation and eco-friendly practices.

Robust Performance in Varied Applications

Handling High Viscosity Fluids

Vertical centrifugal pumps excel at handling high-viscosity liquids commonly found in industries, like petrochemicals and food processing sectors due to their design that enables fluid transfer even for thick liquids while maintaining consistent pressure and flow rates; their flexibility allows them to handle a wide range of substances such, as slurries and viscous oils effectively.

Versatility Across Different Industries

Vertical centrifugal pumps have a range of uses, in industries such as chemical manufacturing and water treatment as well as power generation. They are designed to handle types of fluids like water and chemicals with safety and durability, in mind. Longgang offers a selection of pumps that are tailored to meet the unique performance needs of different sectors.

In summary, vertical centrifugal pumps provide benefits, for management solutions, especially in confined spaces like Longgang. Their functioning energy-efficient features and strong performance in use make them a top pick for industries aiming to enhance their fluid management procedures. Utilizing Longgangs experience, in crafting notch vertical centrifugal pumps further boosts operational efficiency and dependability for global users.

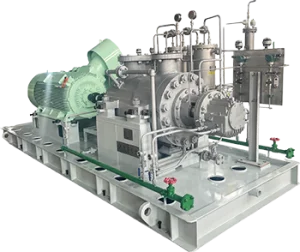

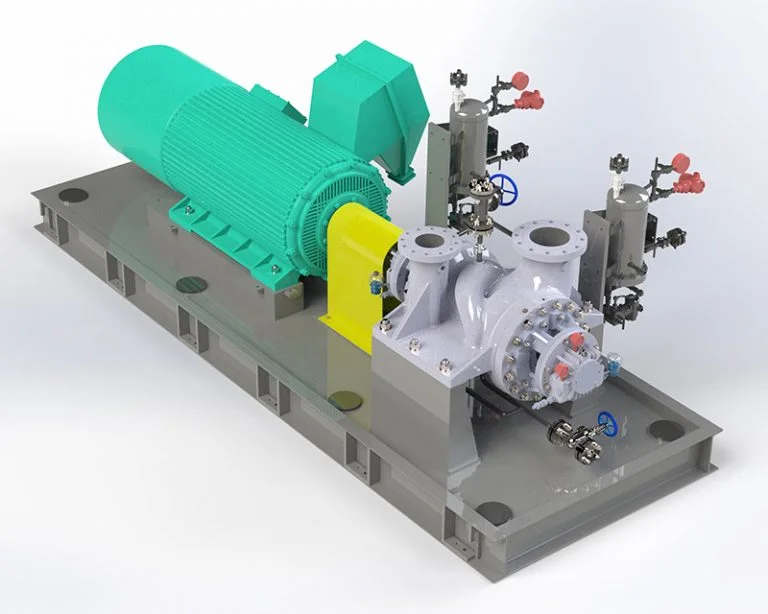

Design Features of Vertical Centrifugal Pumps by Longgang

Materials and Build Quality

Anti-Corrosive Materials Used

Longgangs vertical centrifugal pumps are carefully crafted to resist corrosion effectively by using top-notch materials that can endure fluids typically found in settings. This selection of quality and corrosive materials such, as specific stainless steels and protective coatings not only extends the pump’s lifespan but also boosts the dependability of fluid management processes by maintaining structural integrity over time.

Durability and Longevity Considerations

Longgangs vertical centrifugal pumps are designed to last by incorporating components that can withstand heavy usage over time. The focus is placed on engineering and compliance with standards, like API610. The impellers are carefully crafted to improve efficiency and reduce strain and vibrations, for increased longevity. Moreover, the pumps undergo testing to guarantee they can handle operating conditions resulting in minimal downtime and maintenance requirements.

Customization Options

Tailored Solutions for Specific Needs

Longgang understands the varying needs, in sectors. Provides customization choices for its vertical centrifugal pumps to meet those needs efficiently and effectively. Addressing requirements can be achieved by allowing clients to define features like impeller design, size, and material. This adaptability promotes alignment, with systems resulting in smooth integration and operational performance. Longgangs focus on personalized solutions empowers companies to boost efficiency by optimizing management tailored to their needs.

Industry-Specific Modifications

Longgang recognizes that different industries encounter obstacles that may require adjustments to pump designs. Therefore they provide tailored modifications to suit sectors, like petrochemicals, food processing, and waste management. These adaptations may involve alterations, in sealing techniques updated impeller shapes, or custom casing designs tailored to meet viscosity and temperature criteria. By tailoring their products according to the requirements of industries Longgang guarantees that customers can attain outstanding performance even in the most demanding conditions.

Installation and Maintenance Insights

Installation Requirements and Guidelines

Proper installation is key for vertical centrifugal pumps, from Longgang to work effectively as intended. It’s important that installers position the pumps in a manner to maintain their performance especially due to their vertical design. Ensuring the alignment of the inlet and outlet pipelines is crucial, in order to avoid putting strain by making sure there is no stress placed upon the pump components. Foundation specifications must also be followed closely for stability as inadequate support could result in misalignment and decreased efficiency.

Maintenance Procedures and Intervals

Ease of Access and Replacement Parts Availability

Longgangs vertical centrifugal pumps are crafted to make maintenance tasks more accessible and minimize disruptions efficiently by enabling servicing or replacement of key components, like bearings and seals without the need to dismantle the entire pump unit. Moreoveŕèès readiness with replacement parts is another benefit as they maintain an inventory, for quick maintenance requirements supported by clear documentation and guidelines that assist maintenance staff in adhering to best practices during routine inspections and interventions.

Regular upkeep routines also play a role, in extending the lifespan and ensuring the performance of the pumps while preventing any possible malfunctions that could hinder the fluid management process’s smooth operation. This thorough method of setting up and caring for the equipment guarantees that users get to enjoy the advantages offered by their Longgang centrifugal pumps by reducing downtime and maximizing efficiency.