Chemical pumps leak happens so frequently in many industries. Getting to know the causes and solutions will help you manufacture efficiently.

What is a Chemical Pump?

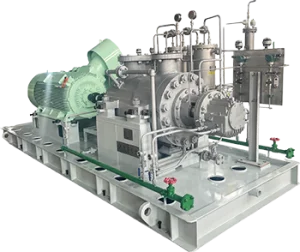

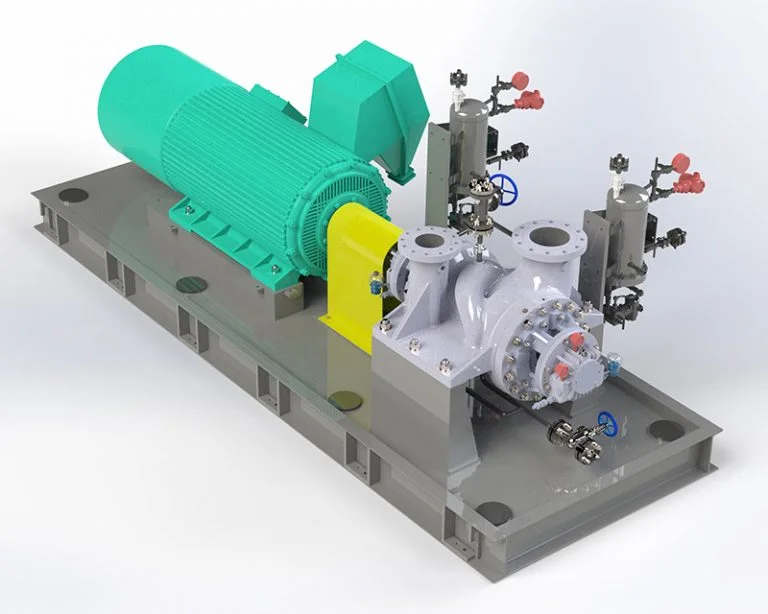

Chemical pumps are specialized devices designed to handle the transfer of chemicals and other corrosive substances. These pumps are essential in industries such as pharmaceuticals, petrochemicals, and wastewater treatment, where they facilitate the safe and efficient movement of hazardous materials.

Features and Advantages of Chemical Pumps

Feature

- Withstand chemical corrosion

- Designed with seals

Advantage

- High durability

- Manage chemicals safely

What Causes Chemical Pumps to Leak?

Chemical pump leaks can result in disruptions and safety risks making it vital to identify the underlying reasons, for incidents to establish reliable preventive measures.

Two Common Factors Leading to Leaks

There are reasons why chemical pumps develop leaks. One of the factors is the wear and tear on seals and other components over time from exposure to harsh chemicals. The problem can also be worsened by installation. Operating the pump beyond its design limits can lead to misalignment and further wear.

Environmental and Operational Influences

The conditions in which a chemical pump functions can greatly impact its durability and performance quality. The integrity of the pump may be compromised by factors such, as temperatures or humidity levels, and exposure to fumes may expedite the deterioration of its components. Additionally, vibrations, from surrounding machinery or fluctuations in pressure levels can strain the pump components resulting in their failure.

How Can You Identify a Leak in a Chemical Pump?

Detecting leaks in chemical pumps at a stage plays a important role in reducing harm and ensuring smooth operations remain intact.

Signs of a Potential Leak

Signs that can be seen like liquid gathering, around the pump’s base or changes in color, on the pump’s surfaces might signal a leak is present. Watch out for noises while it’s running or if the pump is not working effectively as usual. These could indicate internal problems causing leaks.

Diagnostic Tools and Techniques

- Seals

- Gaskets

- thermometer

Specifically, in order to pinpoint leaks accurately and effectively diagnose them a range of tools and methods are utilized in the process. Testing the pressure can uncover vulnerabilities, in seals or gaskets that may lead to leaks. Using thermometer can assist in detecting temperature patterns that might indicate potential fluid leaks. Routine inspections utilizing these tools play a role in identifying issues early to prevent extensive damage, from occurring.

What Are the Effective Strategies to Prevent Leaks?

Ensuring that chemical pumps do not leak requires choosing the equipment and following practices during installation and maintenance procedures.

Choosing the Right Pump for Your Needs

Choosing the chemical pump, for your needs is crucially important in your decision-making process. Take into account elements such as the kind of chemicals it can handle safely and effectively the flow rate that suits your requirements and the conditions under which it will operate. Seek advice from professionals, like Yantai Longgang Pump Industry to make sure you pick a pump model that best fits your situation perfectly.

Implementing Proper Installation Practices

It is essential to install things to prevent leaks effectively so make sure all connections are tight and properly aligned when setting up the system according to the manufacturer’s instructions to prevent any stress points that may cause leaks later.

Regular Maintenance and Inspection Routines

Regular upkeep is crucial in stopping leaks from occurring as time goes by. Make sure to set up checks for parts, such as seals bearings and gaskets. Please replace any worn-out components right away once they are found during inspections.

Seeking out services, for maintenance guarantees inspections performed by skilled technicians who are well-versed in identifying vulnerabilities in various pump models.

By following these steps. Selecting the tools that match your requirements carrying out careful installation processes and regularly checking for any issues. You can minimize the chances of chemical pump leaks and guarantee top-notch performance throughout its operation cycles.

How Can Technology Aid in Leak Prevention?

Incorporating technology, into chemical pump systems is a thinking strategy to reduce leaks effectively. By utilizing the design innovations and integrating monitoring systems you can improve the dependability and security of your operations.

Advancements in Pump Design and Materials

In today’s chemical pump industry advancements in design and materials play a role, in minimizing the chances of leaks occurring significantly. Manufacturers are currently utilizing state-of-the-art materials that provide durability against corrosion and abrasions. The use of these materials results in lifespans for vital components like seals and gaskets – essential, for leak prevention purposes.

Additionally, modern pump designs are centered on reducing the amount of points where leaks could occur. For instance, magnetic drive pumps do away with the requirement, for seals thereby lowering the risk of leaks considerably. By selecting pumps equipped with these characteristics you can lessen maintenance requirements. Improve operational safety.

Integration of Smart Monitoring Systems

Innovative monitoring systems have transformed the way chemical pump operations are overseen by offering insights into pump performance to identify any irregularities that may suggest leaks are signs of concern being highlighted by sensors tracking pressure levels of temperature and vibrations to notify operators of any deviations, from standard operational norms.

Utilizing maintenance techniques, with data analysis assists in recognizing wear trends to cause leaks, in machinery systems. This proactive method not only avoids halts but also prolongs the lifespan of your equipment. By incorporating technologies into your pumping mechanisms operations you enhance efficiency and safety simultaneously.

Why Is Partnering with Longgang Pump Industry?

Partner, with an established company such as Yantai Longgang Pump Industry to avoid chemical pump leaks effectively as their proficiency guarantees solutions, for tackling operational obstacles.

Benefits of Professional Guidance and Support

Working with experts gives you access, to expertise that can boost your efforts in preventing leaks. The professionals at Longgang Pump Industry share advice on choosing the pumps and following top-notch procedures, for installation and upkeep. They offer a range of services to guide you through every stage of the pump lifespan guaranteeing peak performance.

Having expert advice also involves utilizing the technologies and approaches that might not be easily accessible otherwise enabling you to make choices in line, with industry norms and regulatory standards.

Case Studies: Success Stories in Leak Prevention

Numerous companies have effectively addressed issues, with chemical pump leaks by collaborating with the Longgang Pump Industry. For example, a pharmaceutical firm encountered leaks caused by pump materials that didn’t match properly. With guidance from Longgang experts, they switched to pumps crafted from corrosion alloys resulting in a significant drop, in leak occurrences.

For instance, a petrochemical facility incorporated monitoring technology into its current pump configurations. This enhancement enabled the identification of pressure changes that signal seal malfunctions thus avoiding operational halts..

These examples of achievement showcase the outcomes that can result from forming partnerships to enhance operational dependability and safety measures.

FAQs

Q: Does it cost high to fix the pump leaking?

The price of repairing a chemical pump may differ based on the seriousness of the problem and necessary fixes needed to be done on it; nevertheless opting for actions, like routine upkeep and sophisticated monitoring setups commonly turns out to be a more budget-friendly approach compared to dealing with leaks once they happen.

Q: How many chemical pump types?

Various chemical pumps are available for use, such as API pumps and NON-API pumps which have specific features tailored to meet particular operational needs.

Q: What fluid leaks from the chemical pump?

A: The fluid that leaks from a chemical pump depends on its application but typically includes chemicals or corrosive substances being transferred through the system. It is crucial to address any leak promptly due to potential safety hazards associated with hazardous material exposure.

By prioritizing progress and forming collaborations, with industry experts such as Longgang Pump Industry while also addressing frequently asked questions about preventing leaks – your business will see improvements in reliability and a decrease, in the risks tied to chemical pump systems.