What is a Centrifugal Pump?

Centrifugal pumps are the most common fluid conveying equipment in the industrial field. With high efficiency and stable performance, they serve as the core power source in scenarios such as water supply systems, chemical production, and agricultural irrigation.

Click here to learn more about centrifugal pumps.

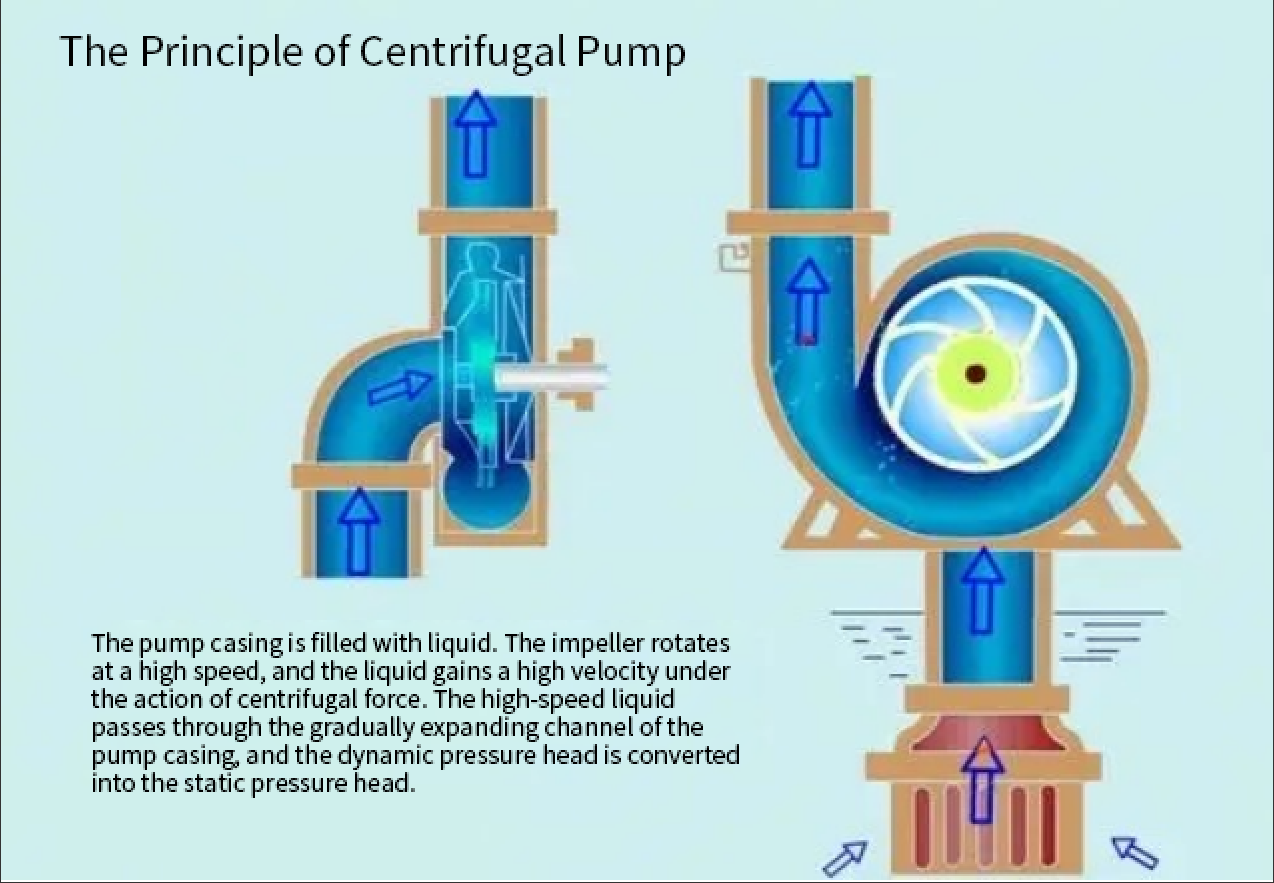

Analysis of the Working Principle of Centrifugal Pumps

The core principle of centrifugal pumps is based on Newton’s second law (F=ma) and fluid dynamics.

When the pump shaft is driven by an electric motor to rotate at a high speed, the vanes on the impeller force the liquid to rotate synchronously with it, generating a strong centrifugal force. Under the action of the centrifugal force, the liquid is thrown towards the edge of the impeller. At this time, the fluid speed can reach 15-30 meters per second, and the kinetic energy is significantly increased. Subsequently, the fluid enters the gradually expanding passage of the volute, where the flow rate decreases and the pressure increases. Finally, it is transported to the target location through the outlet pipeline. This process realizes the conversion from “kinetic energy to pressure energy”, which is similar to converting “high-speed water flow” into “high-pressure water flow”.

- Impeller rotation: The electric motor drives the impeller to rotate at a high speed, generating centrifugal force.

- Fluid suction: The fluid is sucked in from the center (low-pressure area) of the pump body.

- Accelerated discharge: The fluid is discharged at a high speed along the edge of the impeller and enters the pump casing.

- Pressure increase: The diffuser structure of the pump casing reduces the flow rate and increases the pressure.

Check the picture below to intuitively understand the working principle of centrifugal pumps.

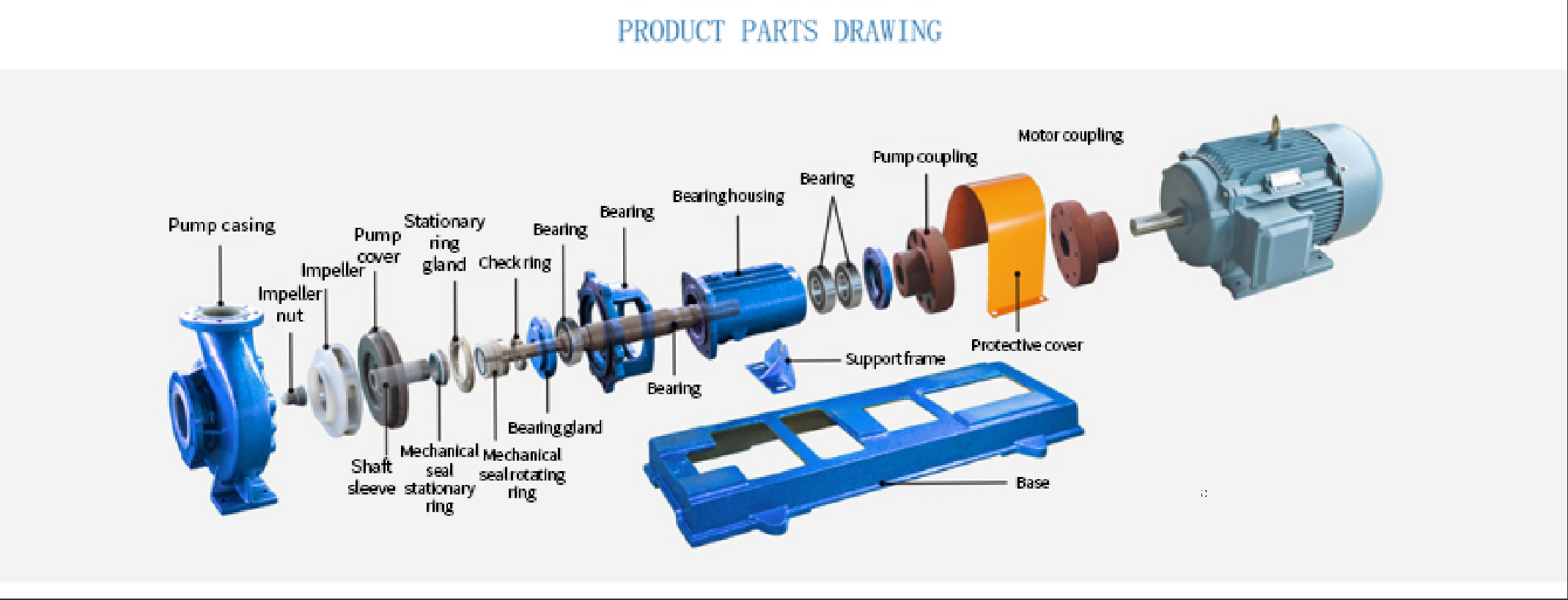

Key Structures of Centrifugal Pumps

Impeller: The core component of a centrifugal pump. The shape of the vanes (such as backward-curved type, radial type) determines the efficiency of fluid acceleration.

Volute: The gradually expanding design decelerates and pressurizes the fluid while collecting the dispersed fluid from the impeller.

Shaft Seal: Prevents the leakage of high-pressure fluid along the pump shaft. Common types include mechanical seals and packing seals.

Suction Chamber: Optimizes the angle at which the fluid enters the impeller and reduces turbulent flow losses.

Application Scenarios of Centrifugal Pumps

Municipal Water Supply: In urban pipe networks, centrifugal pumps lift water from the water source to the water tower, ensuring stable water pressure for thousands of households.

Chemical Production: When conveying corrosive liquids, special centrifugal pumps made of stainless steel or plastic materials are used.

Agricultural Irrigation: High-flow centrifugal pumps can meet the sprinkler irrigation needs of hundreds of acres of farmland.

Aerospace: Miniature centrifugal pumps provide high-pressure liquid oxygen transportation for rocket fuel systems.

Application Cases of Longgang Pump Industry’s Chemical Centrifugal Pumps

Longgang Pump Industry has a deep presence in industries such as petrochemicals, coal chemicals, and environmental protection. Its main products are three major series of centrifugal pumps, namely OH, BB, and VS, in accordance with API standards. In fields such as large-scale oil refining, ethylene production, coal gasification, coal liquefaction, coal-to-methanol, and coal-to-olefins, Longgang Pump Industry has provided a large number of key pump equipment, making important contributions to the development of the industry.

In November 2024, the Sinopec Tianjin Nangang 1.2 million tons per year ethylene and downstream high-end new material industrial cluster project was successfully started up at one time and the entire process was unblocked. In this project, as a key equipment supplier, Longgang Pump Industry provided 12 sets of advanced LDT (VS6) vertical Barrel pumps, covering core equipment such as high-pressure ethylene feed pumps, low-pressure ethylene feed pumps, hydrogenated AGO transfer pumps, PPT unit transfer pumps, and propylene loading pumps.

Longgang Pump Industry has been making continuous progress in the centrifugal pump industry, achieving multiple technological breakthroughs, and continuously providing reliable, intelligent, and efficient centrifugal pump technical solutions.

Click to view more application cases of Longgang Pump Industry.

Conclusion

As the core power equipment of industrial fluid systems, having a deep understanding of the working principle of centrifugal pumps is crucial for their efficient operation. With 22 years of experience in the centrifugal pump field, Longgang Pump Industry provides global customers with one-stop solutions ranging from selection consultation, customized design to lifetime maintenance.

Visit the product center now to obtain more product information, or send an email to discuss cooperation matters!